The necessity of sterilizing medical paraphernalia must be accentuated. Hospital sterilization guarantees patient safety by eradicating deleterious microorganisms from medical items and materials. Although sterilization packaging is widely renowned, additional accessories also upgrade the efficiency of sterilization measures.

Penetrant dye testing for Sealing Processes

The sealing processes and seal quality of sterilization packages are central for preserving sterility and dependability in medicinal pouches, markedly for sensitive goods like surgical instruments. An indispensable technique to authenticate the strong of these seams is the Dye Penetration or Dye Leak Test. This assessment enables medical institutions and firms to mark any imperfections in seam quality.

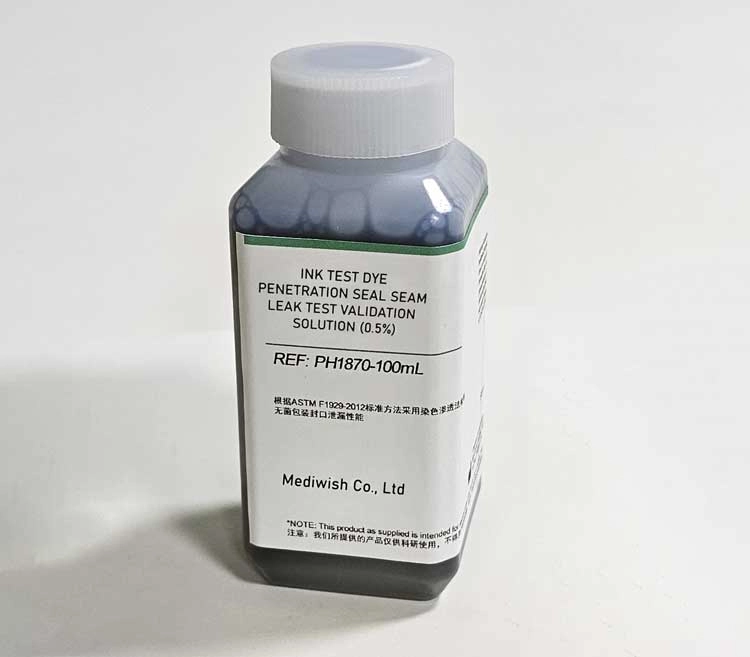

Ink Test: Validation of Seal Seam Leakage

The Ink Test Dye (penetration seal seam leak test approval) is fundamental in surveying sealing implement proficiency. As per ISO 11607-2:2006 standards, this test scrutinizes the manifestation of cavities or opening lines during sealing. By adhering to this examination system, medical sites can attest to the correctness of the sealing pack and impede potential leaks that endanger the sterilization process.

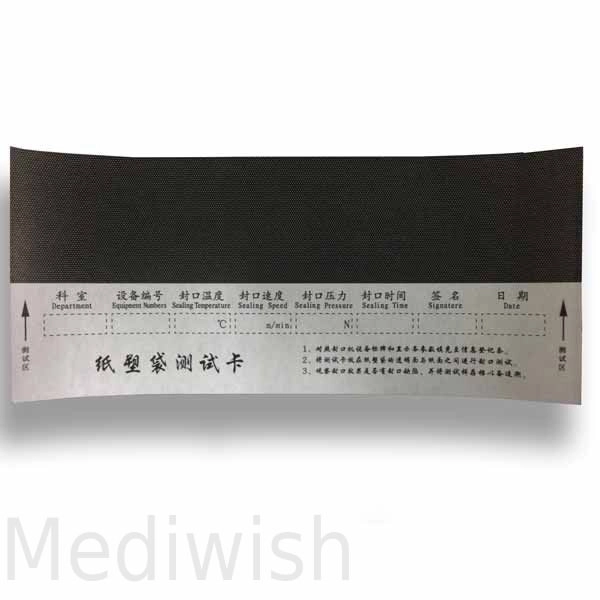

Daily Examining Seal Test Sheet: Guaranteeing Uniform Performance

A daily examining seal test paper is a significant resource for inspecting and ratifying seam performance. By accomplishing regular inspections, medical places can ensure that their sealing undertakings always conform to required Operational Qualification (OQ) norms. This guarantees that seal excellence is retained over time, hindering potential breaches that can influence the sterility condition.

Sterilization Trays: Apposite Arrangement and Preservation

Mediwish® disposable rectangular cardboard trays are designed to adeptly allot products and equipment during the shifting stages of the sterilization process. These trays are vital for steam, ethylene oxide, steam-formaldehyde, and radiation sterilization manners. With a tray size of 240x130x25 mm, they afford:

Sufficient span for managing items.

Maximizing the sterilization process.

Emphasizing the sterility of medical instruments.

Labeling and Documentation Materials: Monitoring and Compliance

Adequate documentation is an essential element of hospital sterilization systems. Labeling materials are crucial in delivering necessary data, incorporating sterilization dates, expiration dates, and batch figures. This comprehensive documentation enables uncomplicated tracking and observation of the sterilization process. Besides, it guarantees acquiescence with regulations and produces an audit record for quality guard purposes.

Protective silicone tips and tubes: Hindering Puncture

Some medical and dental apparatuses have pointed terminuses that may represent the danger of ripping sterilization pouches or wrapping cloths during sterilization. Protective silicone tips and tubes are a reliable answer to this issue. By protecting the sterilization bundle from conceivable harm, these defensive tips and tubes secure the continuous efficacy of the sterilization process.