What is Autoclave Tape?

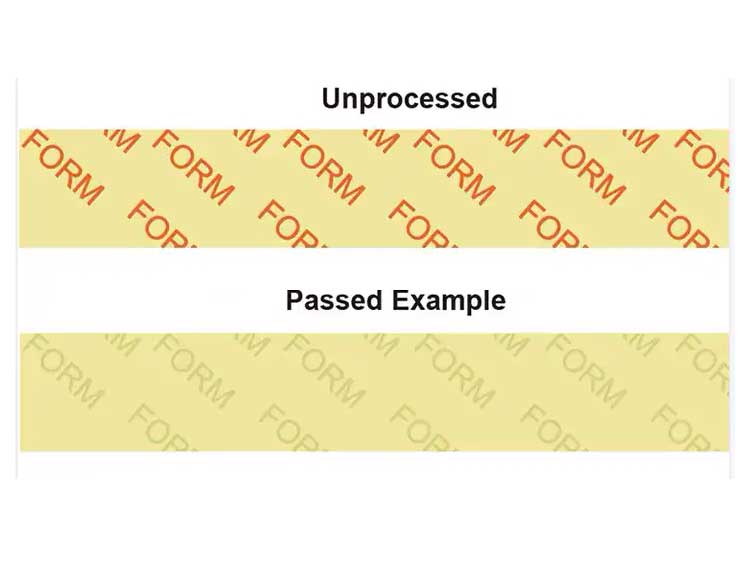

Autoclave steam indicator tape, also known as autoclave tape or steam tape, is a self-adhesive tape that is specifically designed for use in sterilization autoclave. It is applied to the exterior of items or packaging that are to be sterilized. The tape is made with a special ink or chemical that undergoes a distinct color change or pattern alteration when exposed to the high temperature and pressure of steam during the sterilization process.Autoclave Tape Function

The purpose of autoclave steam indicator tape is to provide a visual indication that the items or packaging have been subjected to the appropriate sterilization conditions. By using this sterile tape, healthcare professionals can quickly and easily identify whether the sterilization process has been successful or if any potential issues need to be addressed.

Importance of Autoclave Steam Indicator Tape in Sterilization

The use of autoclave steam indicator tape is essential in ensuring the accuracy and effectiveness of sterilization processes. Without this tape, it would be challenging to determine whether the items or sterilization packs have been adequately sterilized. This can have serious consequences, particularly in healthcare settings where patient safety is of utmost importance.

By using autoclave steam indicator tape, healthcare professionals can have confidence in the sterility of the instruments, equipment, and supplies they use. This tape provides a clear visual indication that the items have been subjected to the necessary steam sterilization process, giving peace of mind and ensuring the safety of patients.

How Does Autoclave Sterilization Tape Work?

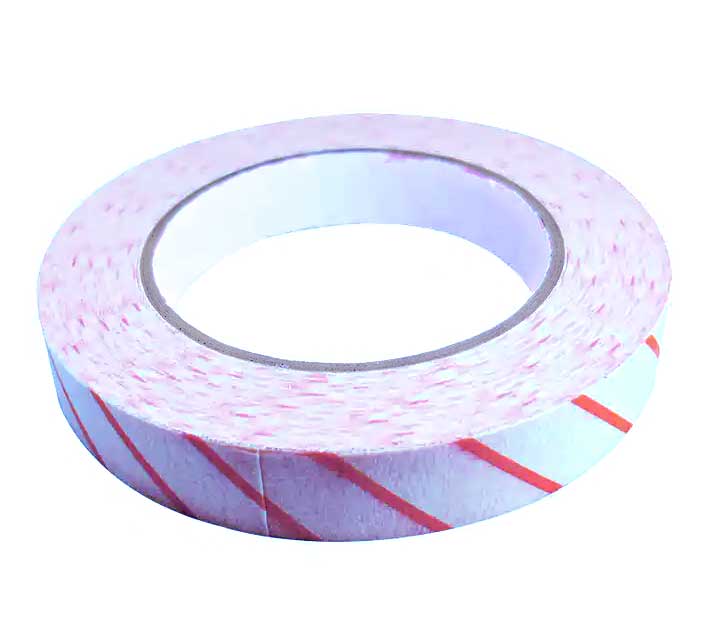

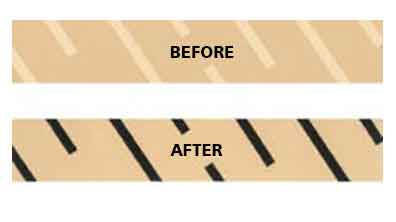

Autoclave steam indicator tape works based on the principle of a chemical or ink that undergoes a distinct color change or pattern alteration when exposed to steam. The tape made from strong crepe paper with a adhesive material and printed on face surface thermochromic ink or a chemical indicator, a specific pattern, for example in the form of diagonal stripes, reminiscent of the stripes on the skin of a zebra, that reacts to the high temperature and pressure of steam. Sterilization Tape Indicator on face surface autoclave tape belong to Class 1 sterilization indicators according ISO 11140-1, so it only serves as a witness to the sterilization process. To determine the quality and completeness of sterilization, it is necessary to use autoclave indicators of a higher class (sterilization strip of class 4, 5 or 6).

Autoclave steam indicator tape works based on the principle of a chemical or ink that undergoes a distinct color change or pattern alteration when exposed to steam. The tape made from strong crepe paper with a adhesive material and printed on face surface thermochromic ink or a chemical indicator, a specific pattern, for example in the form of diagonal stripes, reminiscent of the stripes on the skin of a zebra, that reacts to the high temperature and pressure of steam. Sterilization Tape Indicator on face surface autoclave tape belong to Class 1 sterilization indicators according ISO 11140-1, so it only serves as a witness to the sterilization process. To determine the quality and completeness of sterilization, it is necessary to use autoclave indicators of a higher class (sterilization strip of class 4, 5 or 6).

What color should the autoclave tape be to indicate a package has been sterilized?

During the sterilization process, the tape is applied to the exterior of the items or packaging to be sterilized. As steam penetrates the packaging and reaches the autoclave tape indicator, the heat-sensitive material reacts, causing a visible change in color or pattern from yellow to black. This change serves as an indication that the sterilization process has been successful.

It is important to note that autoclave steam indicator tape is not a substitute for biological indicators (BIs), autoclave indicator strips or other comprehensive sterilization monitoring methods. BIs, such as spore tests, provide a more reliable assessment of the sterilization process by directly measuring the destruction of microorganisms. However, autoclavable tape acts as a quick and convenient visual indicator of successful sterilization.

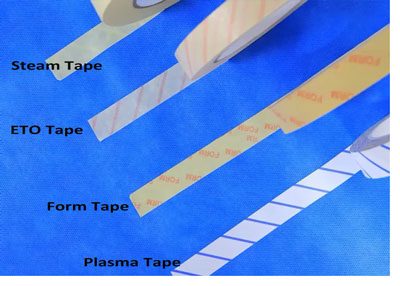

Types of Autoclave Tape

Autoclave tape is available in various types, with different options to suit specific sterilization needs. Here are some of the common types of autoclave tape, according sterilization methods: Steam sterilization, Low temperature sterilization, Dry heat, Ethylene Oxide (EO):

Autoclave tape is available in various types, with different options to suit specific sterilization needs. Here are some of the common types of autoclave tape, according sterilization methods: Steam sterilization, Low temperature sterilization, Dry heat, Ethylene Oxide (EO):

- Autoclave Steam Indicator Tape: This type of tape changes color when exposed to steam sterilizers, providing a clear visual indication of successful sterilization.

- Sterilization Indicator Tape: Sterilization indicator tapes go beyond color changes and provide additional information about the sterilization process. They often feature multiple color changes to indicate specific parameters, such as time, temperature, and pressure.

- Dry Heat Indicator Tape: Dry heat indicator tape is designed for use in dry heat sterilization processes. It undergoes a color change when exposed to high temperatures, indicating the successful sterilization of items.

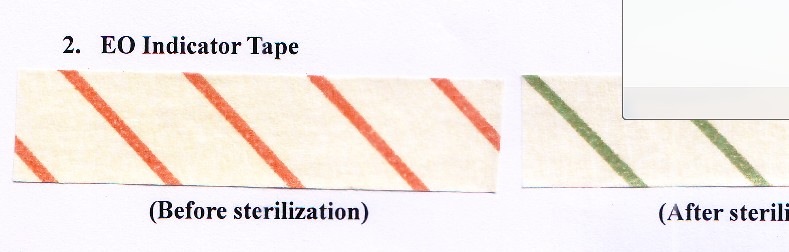

- Ethylene Oxide (EO) Indicator Tape: EO indicator tape is specifically designed for use in sterilization processes that utilize ethylene oxide gas. It changes color when exposed to EO gas, providing a visual indication of successful sterilization.

- Bowie-Dickie Tape: Bowie-Dickie tape is a specialized type of autoclave steam indicator tape used to monitor the performance of vacuum-assisted sterilizers. It undergoes a specific pattern alteration when exposed to the vacuum and steam conditions required for effective sterilization.

- Sterilization Tape without indicator. It is used for reliable hermetically sealing of packaging material (for example, sterilization crepe paper, NON WOVEN SMS wrap, sterilization pouches) where a witness indicator is not required, since there is an autoclave strips of a higher class (for example indicator strips for autoclave 4 class).

Choosing the Right Sterilisation Indicator Tape for Your Needs

When selecting autoclave steam indicator tape, it is important to consider the specific requirements of your sterilization process. Here are some factors to consider when choosing the right tape for your needs:

- Compatibility with sterilization methods: Ensure that the sterilization tape is compatible with the materials and packaging you are sterilizing. Some tapes may not adhere well to certain surfaces or may not provide reliable indications when used with specific packaging materials.

- Size: Autoclave tape in roll manufactured with different width and lenght. Available width size: 10,12,15,18,19,20,24,25,30 mm, Lenght: 25,30,50,55 meters.

- Color Contrast: Look for tapes that provide a clear and distinct color change or pattern alteration. This ensures that the visual indication is easily visible and identifiable.

- Additional Information: If you require more detailed information about the sterilization process, consider using sterilization tape that provide multiple color changes to indicate various parameters such as time, temperature, and pressure.

- Regulatory Compliance: Ensure that the autoclave steam indicator tape meets relevant regulatory standards and guidelines for sterilization processes in your industry or region.

By considering these factors, you can choose the right sterilization tape that provides accurate and reliable indications of successful sterilization.

Using Autoclave Tape Dispenser for Easy Application

To ensure the efficient and accurate application of autoclave steam indicator tape, it is recommended to use a tape dispenser specifically designed for this purpose. Autoclave tape dispensers are designed to hold and dispense the tape smoothly, allowing for quick and easy application.

To ensure the efficient and accurate application of autoclave steam indicator tape, it is recommended to use a tape dispenser specifically designed for this purpose. Autoclave tape dispensers are designed to hold and dispense the tape smoothly, allowing for quick and easy application.

Using a tape roll dispenser offers several advantages:

- Consistent Application: The dispenser ensures that the tape is applied evenly and consistently, reducing the risk of incomplete or uneven coverage.

- Ease of Use: Dispensers provide a convenient way to handle the tape, allowing for efficient application without the need for manual cutting or handling.

- Time-Saving: By using a dispenser, healthcare professionals can save time during the sterilization process, enabling them to focus on other critical tasks.

Autoclave tape dispensers are available in various sizes and designs to accommodate different tape widths. When purchasing a tape dispenser, ensure that it is compatible with the tape you intend to use.

Common Misconceptions about Autoclave Steam Indicator Tape

Despite the importance and widespread use of autoclave steam indicator tape, there are some common misconceptions surrounding its purpose and effectiveness. Let's address a few of these misconceptions:

- Misconception 1: Autoclave steam indicator tape is a substitute for biological indicators (BIs).

Fact: While autoclave steam indicator tape provides a visual indication of successful sterilization, it is not a substitute for BIs. BIs, such as spore tests, provide a more comprehensive assessment of the sterilization process by directly measuring the destruction of microorganisms.

- Misconception 2: All autoclave steam indicator tapes are the same.

Fact: Autoclave steam indicator tapes come in various types, each designed to meet specific sterilization methods needs. It is important to choose the appropriate type of tape based on your specific requirements.

- Misconception 3: Autoclave steam indicator tape can be reused.

Fact: Autoclave steam indicator tape is designed for single-use only. Once it has been exposed to the sterilization process, it should be discarded and replaced with a new piece of tape for subsequent sterilizations.

By dispelling these misconceptions, healthcare professionals can better understand the role and limitations of autoclave steam indicator tape in ensuring sterilization accuracy.

Best Practices for Using Autoclave Steam Indicator Tape

Best Practices for Using Autoclave Steam Indicator Tape

Best Practices for Using Autoclave Steam Indicator Tape

Autoclave sterilization is a critical process that ensures the proper sterilization of medical instruments and equipment. One essential tool in this process is autoclave steam indicator tape. But what is autoclave tape, and why is it important?

Autoclave tape, also known as autoclavable tape or autoclave tape indicator, is specifically designed to provide a visual indication of successful sterilization. It contains chemical indicators that change color when exposed to the high temperatures and steam of the autoclave. These indicators are crucial in validating the effectiveness of the sterilization process.

When using autoclave indicator tape, it is essential to follow a few best practices to ensure accurate results. First and foremost, always check the tape's expiration date. Like any other medical supply, indicator tape has a shelf life, and using expired tape can compromise the accuracy of the results.

Before using the autoclave tape, inspect it for any damage or discoloration. Ensure that the tape is intact and that the indicators are evenly distributed. Any abnormalities may affect the tape's performance, leading to inaccurate readings.

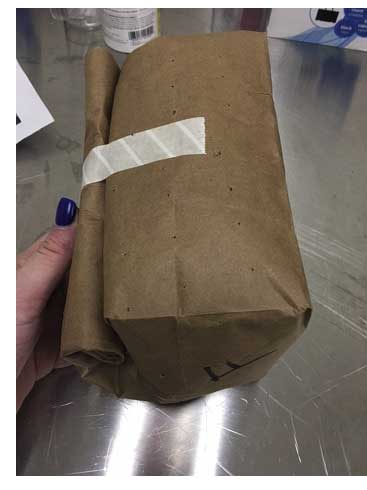

To apply the tape correctly, wrap it around the materials or instruments to be sterilized, ensuring that it covers the entire surface area. Place the wrapped items in the autoclave and proceed with the sterilization process as usual.

During the autoclave cycle, the tape's chemical indicators react to the steam and temperature, resulting in a noticeable color change. This change indicates that the sterilization process was successful. After the cycle is complete, carefully inspect the tape. The color change should be uniform across the tape's length, confirming that all parts of the material received adequate sterilization.

It is crucial to remember that autoclave indicator tapes are single-use items. They should be discarded after each cycle, even if the color change indicates successful sterilization. Reusing indicator tape can lead to inaccurate results and compromise patient safety.

Now that you understand the importance of autoclave indicator tape let's address some common questions. What is autoclave tape, and how does it work? Autoclave tape is an instrument tape that is specifically designed to be autoclavable. It functions by containing chemical indicators that change color when exposed to the sterilization process. This color change serves as a visual confirmation that the materials have been properly sterilized.

Autoclave indicator strips, also known as indicator strips for autoclave and sterilization indicator tape, function in a similar manner. They provide visual confirmation of sterilization by changing color when exposed to the necessary temperature and steam.

Lastly, the question remains: what is autoclave tape's function, and how much does it cost? Autoclave tape's primary function is to provide a quick and reliable visual indication of successful sterilization. As for the cost, it varies depending on the brand, quantity, and supplier. It is recommended to check with your healthcare provider or supplier for the current autoclave tape prices.

In conclusion, autoclave steam indicator tape plays a vital role in ensuring the effectiveness of the sterilization process. By following best practices and understanding the purpose of autoclave tape, healthcare professionals can confidently validate the sterilization of medical instruments and equipment.

To maximize the effectiveness of autoclave steam indicator tape and ensure accurate sterilization, it is important to follow best practices. Here are some tips to consider when using autoclave steam indicator tape:

- Proper Application: Ensure that the tape is properly applied to the items or packaging to be sterilized. The tape should be securely adhered and cover a sufficient area to provide a reliable indication.

- Placement: Place the tape in a visible and easily accessible location on the packaging to allow for quick visual inspection.

- Avoid Overlapping: Avoid overlapping multiple layers of tape, as this can hinder the accuracy of the color change or pattern alteration.

- Recordkeeping: Maintain detailed records of sterilization processes, including the use of autoclave steam indicator tape. This documentation can be valuable for quality assurance and compliance purposes.

By following these best practices, healthcare professionals can ensure that autoclave steam indicator tape is used effectively and reliably in their sterilization processes.

Where to Buy Autoclave Steam Indicator Tape and Average Prices

Autoclave steam indicator tape is readily available from a wide range of suppliers. Here are some common sources where you can purchase autoclave steam indicator tape:

- Medical Supply Stores: Local medical supply stores often carry autoclave steam indicator tape. Visit your nearest store or check their online catalogs for options.

- Online Retailers: Many online retailers specialize in medical and laboratory supplies, including autoclave steam indicator tape. Websites such as Amazon, eBay, and specialized medical supply websites offer a wide selection of tapes to choose from.

- Manufacturer Websites: Some manufacturers of autoclave steam indicator tape sell their products directly through their websites. Visiting the manufacturer's website can provide information about their offerings and pricing.

The price of autoclave steam indicator tape can vary depending on factors such as the type of tape, quantity, and brand. On average, a roll of autoclave tape fluctuation price can range from $1 to $20. It is recommended to compare prices from different suppliers to ensure you are getting the best value for your needs.

Other Types of Sterilization Indicator Tapes

In addition to autoclave steam indicator tape, there are other types of sterilization indicator tapes available for different sterilization processes. Here are a few examples:

- Chemical Indicator Tape: Chemical indicator tape is used in various sterilization processes, including ethylene oxide (EO) gas sterilization, hydrogen peroxide plasma sterilization, and dry heat sterilization. These tapes undergo specific color changes to indicate successful sterilization.

- Dry Heat Indicator Tape: Dry heat indicator tape is designed specifically for dry heat sterilization processes. It changes color when exposed to high temperatures, providing a visual indication of successful sterilization.

- EO Indicator Tape: EO indicator tape is used specifically for ethylene oxide gas sterilization processes. It changes color when exposed to EO gas, indicating successful sterilization.

- Plasma indicator tape. Adhesive tapes with marker suitable for VH2O2 furnace which meet the following technical characteristics:

- Intended for use in SMS wrapping material .

- The tape made of polyester or polypropylene film, white in color, have a strong adhesive that firmly secures the packages, be removed easily and uniformly without leaving any residue.

- Uniformly and compactly applied to the inner cylinder and not to create air gaps between its various layers.

- To carry a built-in chemical indicator suitable for sterilization in a VH2O2 furnace (plasma indicator tape), of a sharp color change from blue/purple to pink.

- The expiry date and production batch indicated on the inner hollow of the film or on each individual package .

- Dimensions: 24 mm ±1 mm x 25m – 30m

- Elongation: ≥7% Tensile strength: ≥8 0 N/25mm

- Adhesion to steel: ≥10N/25mm

- Compliance with the European standard : EN 11140-1:2014 (Sterilization of health care products — Chemical indicators - Part 1: General requirements).

- The films individually packaged (Unit packaging ), in original polyethylene (PE) packaging, to protect against dust cover ).

- The original packaging in a second packaging [ shipping case )], which contains a maximum of 48 pcs.

These are just a few examples of the different types of sterilization autoclave tape indicator available. It is important to choose the appropriate tape for the specific sterilization process you are using.

Conclusion: Ensuring Sterilization Accuracy with Autoclave Steam Indicator Tape

Achieving sterilization accuracy is crucial in healthcare settings and other industries where sterility is paramount. Autoclave steam indicator tape plays a vital role in this process by providing a visual indication of successful sterilization. By understanding the importance of autoclave steam indicator tape, how it works, the different types available, and best practices for its use, healthcare professionals can ensure the safety and effectiveness of their sterilization processes.

Whether you are purchasing autoclave steam indicator tape for your healthcare facility or laboratory, it is important to choose the right tape for your specific needs. Consider factors such as compatibility, color contrast, additional information provided, and regulatory compliance when selecting the tape that best meets your requirements.

Remember to follow best practices when using autoclave steam indicator tape, including proper application, placement, and recordkeeping. This ensures that the tape is used effectively and reliably in your sterilization processes.

Lastly, autoclave steam indicator tape can be easily purchased from medical supply stores, online retailers, or directly from manufacturers. Compare prices and options to find the best value for your needs.

By using autoclave steam indicator tape and following these guidelines, you can ensure the accuracy and safety of your sterilization processes, providing peace of mind and protecting the well-being of patients and users.