Unlocking the Secrets of Chemical Indicators in Sterile Processing

Introduction

In the realm of sterile processing, ensuring the efficacy of sterilization processes is paramount. Chemical indicators play a pivotal role in this landscape, serving as vigilant guardians of patient safety by providing real-time feedback on sterilization success. This article delves into the intricacies of chemical indicators, shedding light on their types, functions, and indispensable role in maintaining optimal healthcare standards.

Understanding Chemical Indicators

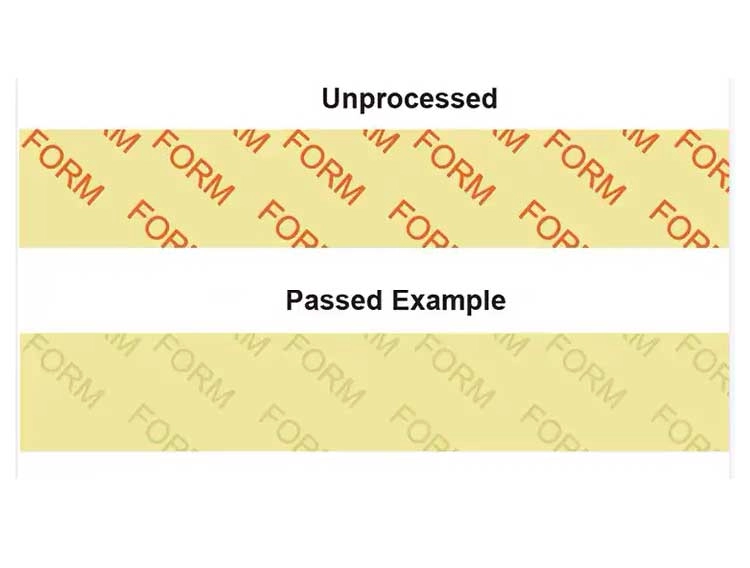

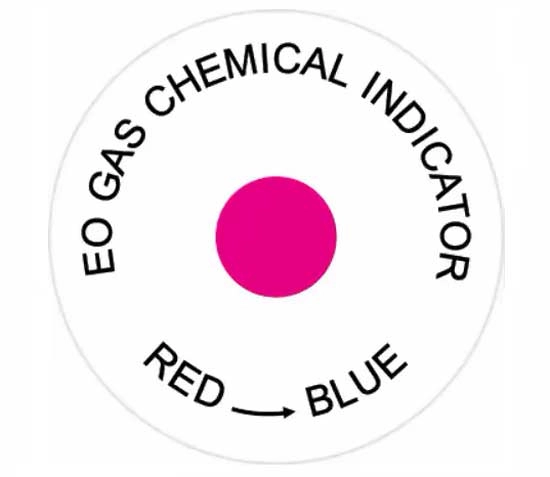

Chemical indicators are indispensable tools in the sterile processing toolkit. They are designed to undergo a visible change when exposed to specific sterilization conditions, indicating that the desired parameters for sterilization have been met. This immediate feedback is crucial for healthcare facilities to ascertain the effectiveness of their sterilization processes.

Types of Chemical Indicators

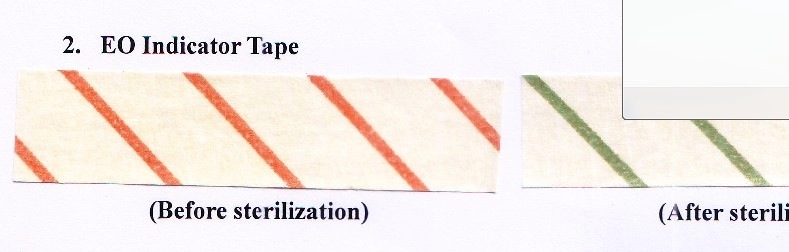

- Class 1: Process Indicators

-

- Purpose: Confirming the exposure to a sterilization process.

- Visual Change: Often involves a color shift or pattern alteration.

- Class 2: Bowie-Dick Type Indicators

-

- Purpose: Primarily used in steam sterilizers to detect air removal issues.

- Visual Change: Indicates the presence of air by color transition or pattern change.

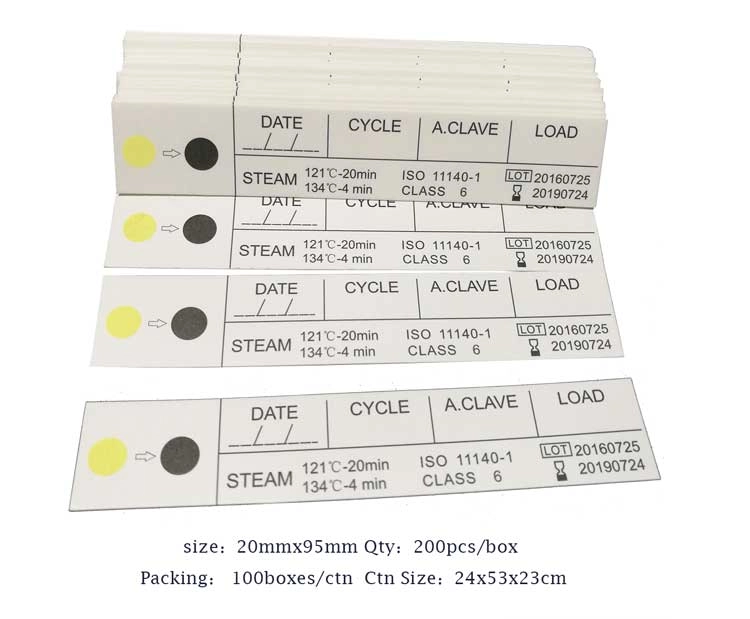

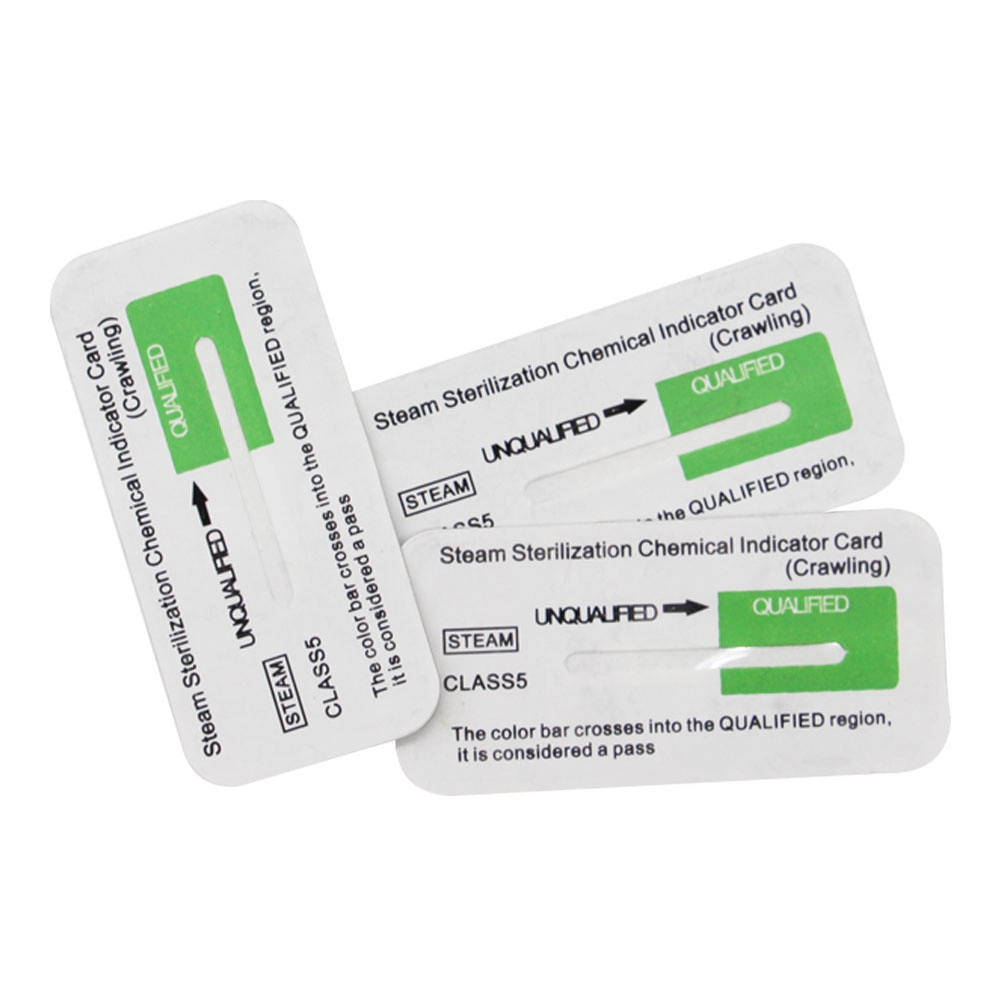

- Class 3: Single-Parameter Indicators

-

- Purpose: Monitoring specific parameters like time, temperature, or gas concentration.

- Visual Change: Tailored to the parameter being monitored, providing a clear signal of compliance.

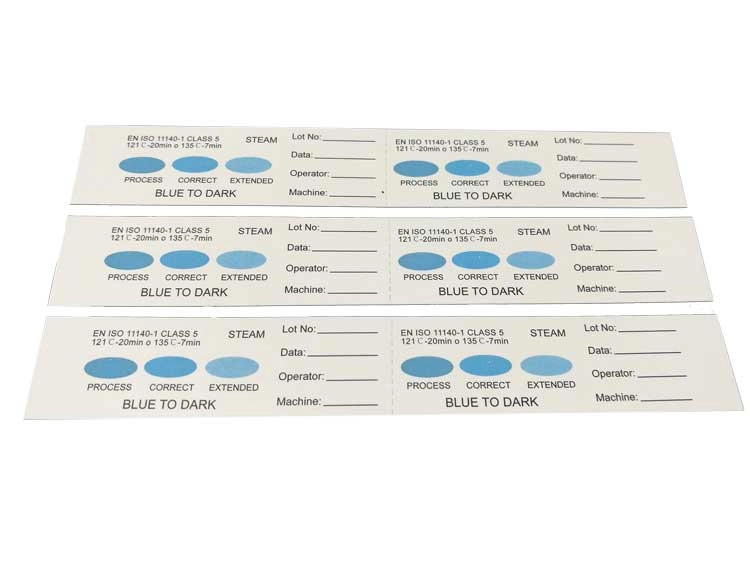

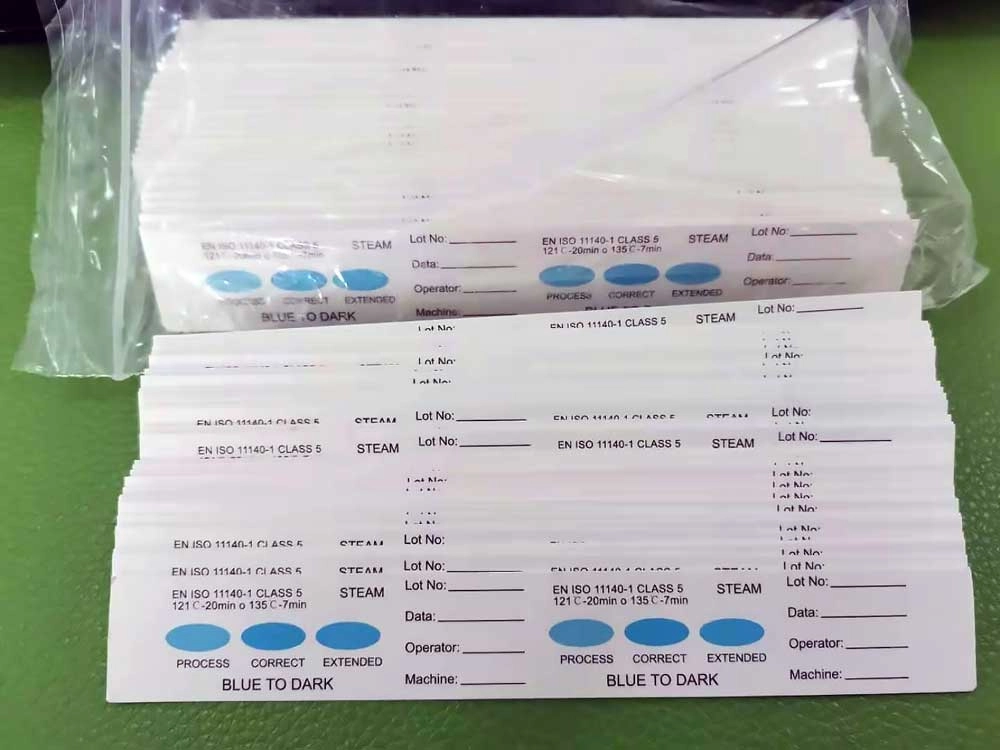

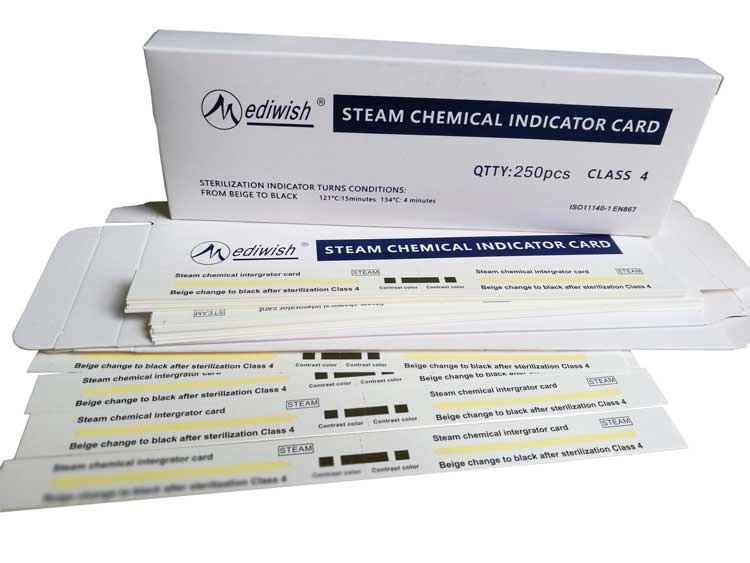

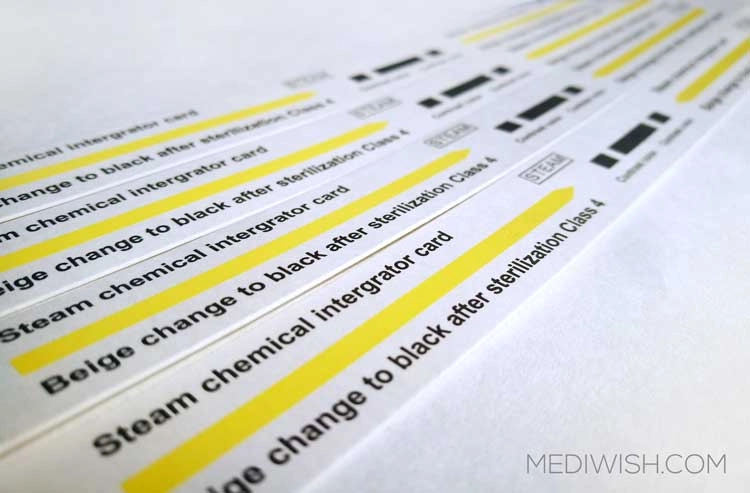

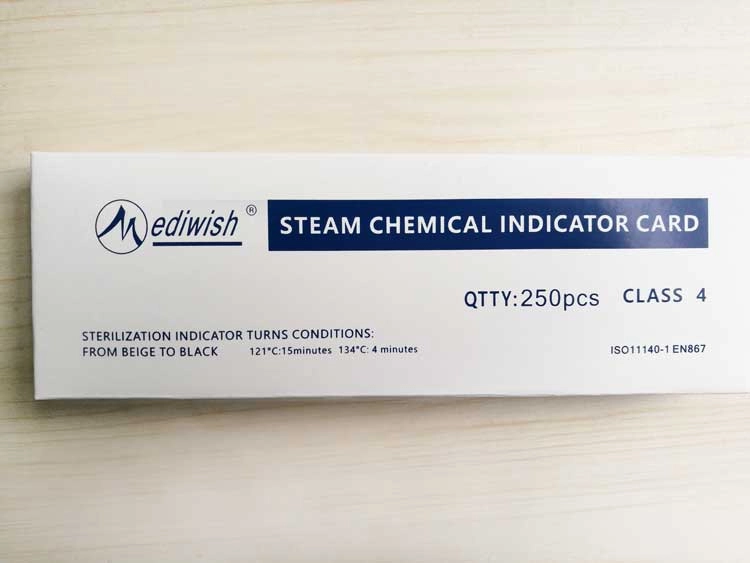

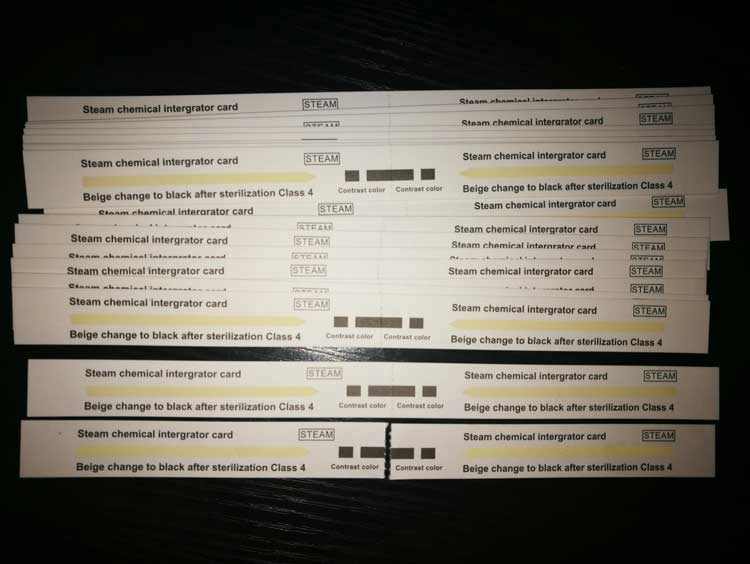

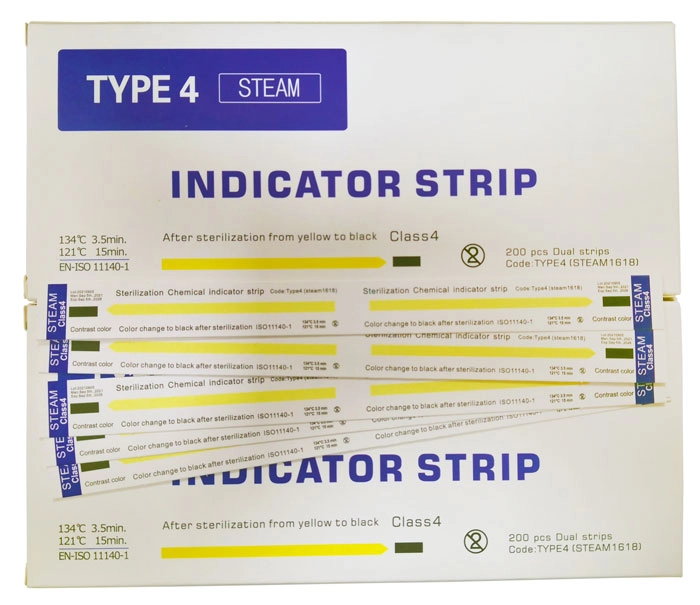

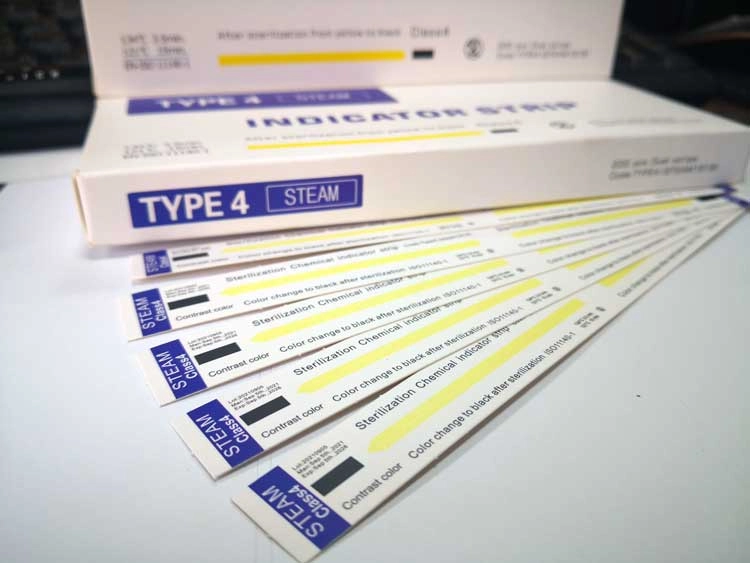

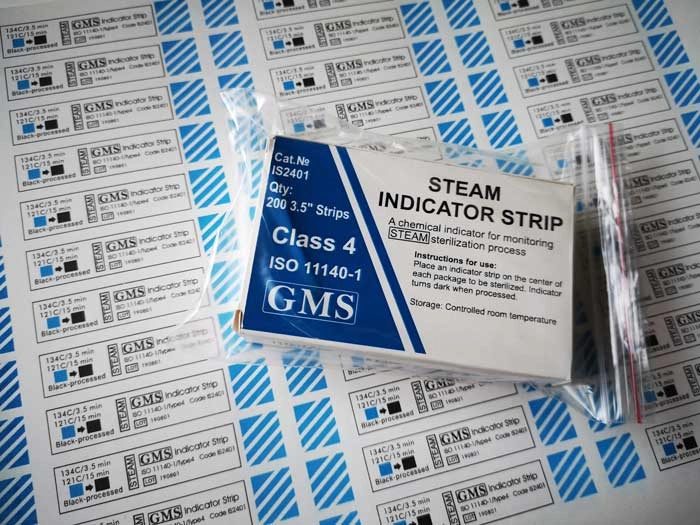

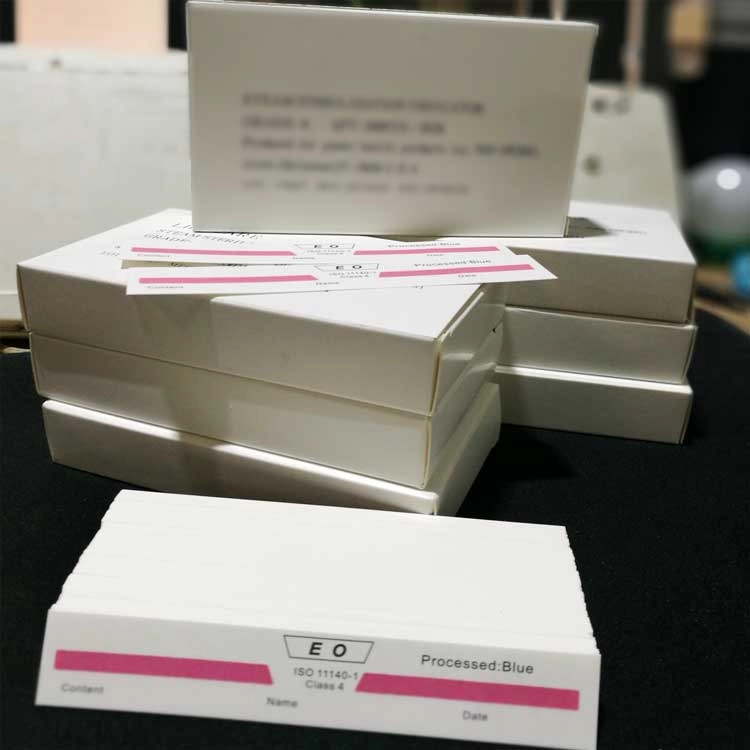

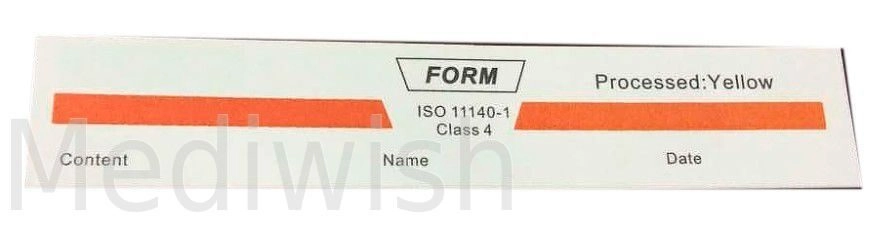

- Class 4: Multi-Parameter Indicators

-

- Purpose: Comprehensive monitoring of multiple sterilization parameters.

- Visual Change: Multiple indicators within a single device responding to different parameters.

The Significance of Chemical Indicators in Sterile Processing

Ensuring Patient Safety

The primary function of chemical indicators is to uphold patient safety by validating the efficacy of sterilization processes. This validation is critical in preventing the transmission of infections and maintaining the highest standards of healthcare.

Regulatory Compliance

Healthcare facilities must adhere to stringent regulations. Proper use of chemical indicators not only ensures compliance with these standards but also facilitates documentation, an essential aspect of regulatory requirements.

Equipment Monitoring

Chemical indicators not only validate the success of sterilization but also serve as diagnostic tools for monitoring the performance of sterilization equipment. Regular monitoring helps identify issues promptly, ensuring uninterrupted operation.

Choosing the Right Chemical Indicator

Selecting the appropriate chemical indicator is a nuanced process that depends on the sterilization method, equipment, and specific requirements of the healthcare facility. Factors such as sensitivity, accuracy, and ease of interpretation play a crucial role in this selection process.

Conclusion

In the dynamic landscape of sterile processing, the judicious selection and use of chemical indicators are non-negotiable. This article has provided a comprehensive overview of the types, significance, and selection process of chemical indicators, aiming to equip healthcare professionals with the knowledge needed to uphold the highest standards of patient safety and regulatory compliance. As the healthcare industry evolves, staying informed about advancements in chemical indicators remains imperative for delivering optimal care.