EO Gas: The Safest and Most Effective Method for Sterilization

How EO Gas sterilization works

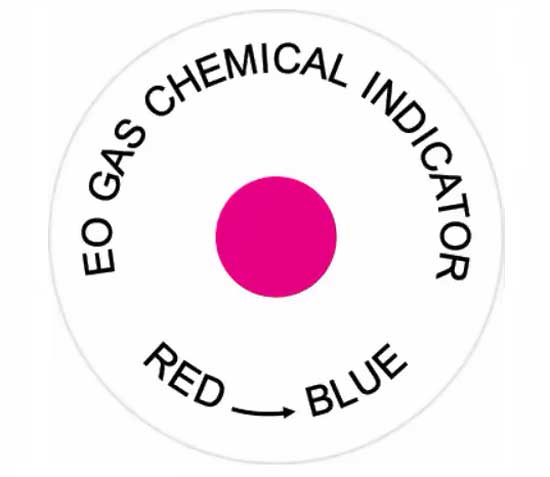

EO Gas sterilization, also known as ethylene oxide sterilization, is a process that uses ethylene oxide gas to eliminate microorganisms from various items. Ethylene oxide is a colorless, flammable gas that has excellent penetrating properties, allowing it to reach even the most hard-to-reach areas of the items being sterilized. The process involves exposing the items to a controlled environment, typically within a sealed chamber, where a combination of temperature, humidity, and EO Gas concentration is carefully regulated to achieve optimal sterilization.

During the sterilization process, EO Gas interacts with the microorganisms by disrupting their cellular structures and inhibiting their ability to reproduce. This ensures that the items being sterilized are free from bacteria, viruses, fungi, and other harmful pathogens. EO Gas sterilization is particularly effective against heat-sensitive materials, such as plastics, rubber, and electronics, where other sterilization methods may cause damage or deformation.

Advantages of using EO Gas for sterilization

EO Gas sterilization offers several advantages over other sterilization methods. Firstly, its excellent penetrating ability allows it to reach all areas of the items being sterilized, ensuring thorough sterilization. This is especially crucial for complex instruments with intricate designs or items with multiple layers, where other methods may struggle to achieve the same level of effectiveness.

Secondly, EO Gas sterilization is compatible with a wide range of materials, including plastics, metals, glass, and fabrics. This versatility makes it suitable for sterilizing various items in different industries, from medical devices and pharmaceutical products to food packaging materials. Unlike other sterilization methods that may damage or degrade certain materials, EO Gas sterilization is gentle yet highly effective.

Lastly, EO Gas sterilization leaves no residue on the sterilized items. After the sterilization process is complete, the EO Gas rapidly dissipates, leaving no toxic or harmful substances behind. This is particularly important for items that come into direct contact with patients or consumers, as it eliminates the risk of exposure to residual chemicals.

Common applications of EO Gas sterilization

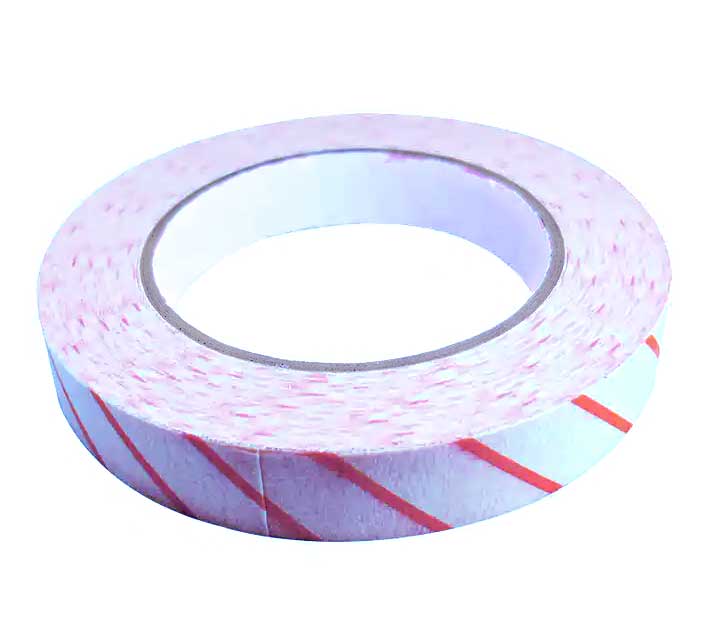

EO Gas sterilization finds extensive use in a wide range of industries due to its effectiveness and compatibility with various materials. In the healthcare sector, it is commonly employed to sterilize medical devices, surgical instruments, and implants. Pharmaceuticals and biotechnology companies also rely on EO Gas sterilization to ensure the sterility of their products, such as drug vials, syringes, and IV sets.

Furthermore, EO Gas sterilization is crucial in the food industry for preserving the quality and safety of packaged food products. It is used to sterilize food packaging materials, such as plastic trays and containers, to prevent the growth of bacteria and extend shelf life. Additionally, EO Gas sterilization is employed in the manufacturing of electronic components and precision equipment, where maintaining sterility is vital to prevent contamination and malfunction.

Safety precautions and regulations for EO Gas sterilization

While EO Gas sterilization offers numerous benefits, it is essential to adhere to strict safety precautions and regulations to ensure the well-being of workers and the environment. The Occupational Safety and Health Administration (OSHA) and other regulatory bodies have established guidelines for the safe use of EO Gas, including proper handling, storage, and ventilation requirements. These regulations aim to minimize the exposure to EO Gas, which can have harmful effects on human health.

To ensure safety, it is crucial to have proper training and personal protective equipment for workers involved in EO Gas sterilization processes. Adequate ventilation systems should be in place to prevent the accumulation of EO Gas in work areas. Monitoring devices should also be utilized to measure and maintain safe EO Gas levels. Additionally, proper disposal procedures should be followed to prevent environmental contamination.

Comparing EO Gas sterilization to other sterilization methods

When comparing EO Gas sterilization to other sterilization methods, such as steam, dry heat, or radiation, each method has its advantages and limitations. Steam sterilization, also known as autoclaving, is widely used due to its effectiveness and low cost. However, it may cause damage to heat-sensitive materials and cannot penetrate certain types of packaging.

Dry heat sterilization, on the other hand, is suitable for items that are sensitive to moisture. It utilizes hot air to eliminate microorganisms but requires longer exposure times and higher temperatures compared to EO Gas sterilization. Radiation sterilization, including gamma and electron beam irradiation, is effective but may cause changes in the physical properties of materials.

EO Gas sterilization, with its excellent penetrating ability and compatibility with various materials, overcomes many of the limitations of other methods. It is particularly advantageous for heat-sensitive items, delicate instruments, and complex devices. Additionally, EO Gas sterilization leaves no residue and does not require high temperatures, making it a preferred choice for many industries.

The history and development of EO Gas sterilization

The use of ethylene oxide for sterilization dates back to the early 20th century when it was discovered that EO Gas could effectively kill microorganisms. Over the years, advancements in technology and understanding of EO Gas sterilization have led to the development of safer and more efficient processes. The introduction of computer-controlled systems, improved monitoring devices, and better understanding of EO Gas concentrations have contributed to enhancing the sterilization process.

Moreover, the development of EO Gas cartridges and pre-filled canisters has simplified the sterilization process, making it more accessible to smaller facilities and clinics. These innovations have not only improved the safety and efficiency of EO Gas sterilization but also reduced the overall cost and time required for the process.

Ethylene Oxide (ETO) vs. EO Gas: Understanding the difference

The terms "ethylene oxide" (ETO) and "EO Gas" are often used interchangeably, but it is important to understand the subtle differences between the two. Ethylene oxide refers to the pure chemical compound, which is a gas at room temperature. On the other hand, EO Gas refers to the mixture of ethylene oxide and an inert gas, such as carbon dioxide or nitrogen, which is used for sterilization purposes.

The addition of an inert gas to ethylene oxide helps to stabilize the gas mixture, making it safer to handle and transport. It also aids in achieving the desired concentration and distribution of EO Gas during the sterilization process. Therefore, when discussing sterilization methods, it is more accurate to refer to EO Gas sterilization rather than ethylene oxide sterilization.

Ethylene Oxide (ETO) sterilization process explained

The ethylene oxide sterilization process involves several stages to ensure effective sterilization while maintaining safety. The first step is the pre-conditioning phase, during which the items to be sterilized are exposed to controlled humidity to optimize the sterilization process. This is followed by the actual sterilization phase, where the items are placed in a sealed chamber and exposed to EO Gas for a specific duration.

After the sterilization phase, the items undergo aeration to remove the residual EO Gas. Aeration typically involves exposing the items to a controlled environment with increased airflow and temperature to facilitate the removal of EO Gas. This step is crucial to ensure that the sterilized items are safe for use, as residual EO Gas can be harmful to individuals.

The entire ethylene oxide sterilization process is carefully monitored, with parameters such as temperature, humidity, and EO Gas concentration continuously measured and adjusted as needed. This ensures consistent and reliable sterilization results while adhering to safety regulations.

Conclusion: Why EO Gas is the safest and most effective method for sterilization

EO Gas sterilization stands out as the safest and most effective method for sterilization due to its excellent penetrating ability, compatibility with various materials, and lack of residue. It is widely utilized in the healthcare, pharmaceutical, food, and electronics industries, among others, to ensure the sterility of items and prevent contamination.

By following strict safety precautions and regulations, such as proper handling, ventilation, and disposal procedures, EO Gas sterilization can be performed safely while minimizing the risks to workers and the environment.

When compared to other sterilization methods, EO Gas sterilization overcomes many limitations, making it a preferred choice for heat-sensitive materials and delicate instruments. Advancements in technology have further enhanced the efficiency and accessibility of EO Gas sterilization, making it an indispensable process in numerous industries.

In conclusion, EO Gas sterilization provides a reliable and efficient solution for maintaining sterility and preventing infections. Its widespread use is a testament to its effectiveness and safety. As industries continue to evolve, EO Gas sterilization will undoubtedly remain a critical process for ensuring the highest standards of hygiene and product quality.

To learn more about the advantages of EO Gas sterilization and how it can benefit your industry, contact our experts at Mediwish Co., Ltd. Ensure the safety and quality of your products with the most effective sterilization method available.