Choosing the Best Sterilization Wrap for Medical Excellence

In the fast-paced world of healthcare, maintaining the highest standards of sterility is paramount. This critical need extends to the instruments, supplies, and equipment used in medical and dental practices. Enter Mediwish® Sterilization Wrap, a game-changer in the realm of barrier wrap, offering impeccable protection and convenience for healthcare professionals. With its outstanding features, including impressive strength and flexibility, Mediwish® Sterilization Wrap stands out as a top choice for ensuring sterility maintenance, making sure your sets are always ready for action.

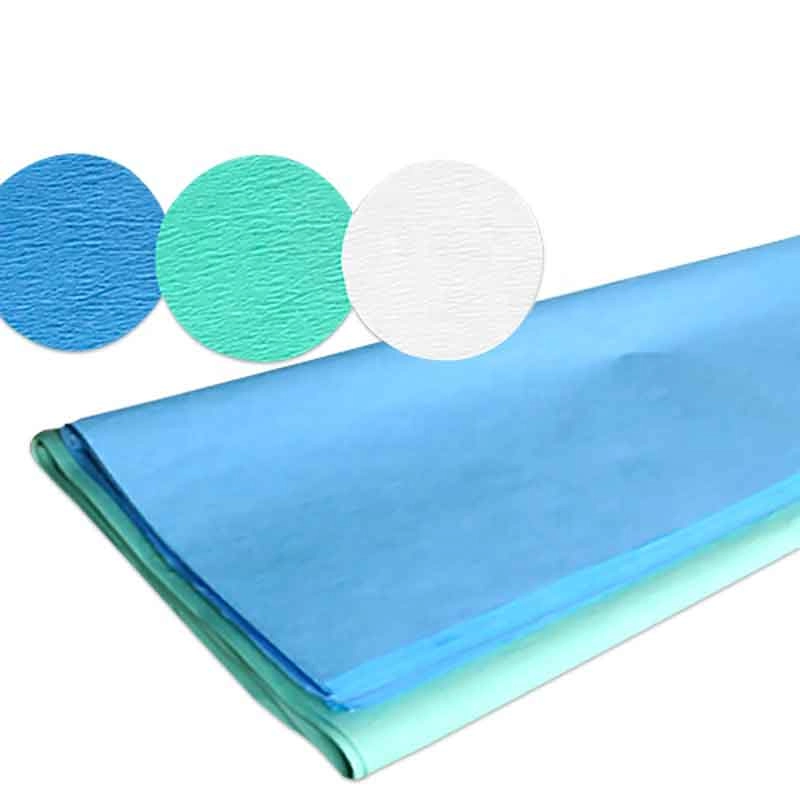

One standout feature of Mediwish® Sterilization Wrap is its remarkable strength, boasting up to 30% more robustness compared to other options on the market. This increase in strength comes without compromising on the wrap's flexibility, making it an indispensable tool in the pursuit of medical excellence. Beyond its strength and flexibility, Mediwish® Sterilization Wrap offers an added advantage with its contrasting colors, available in both blue and green. These colors not only lend a touch of vibrancy but also play a crucial role in supporting visualization during aseptic presentations in the operating room.

The Vital Role of Sterilization Wrap

Sterilization wrap, also commonly referred to as sterile wrap, plays a pivotal role in the healthcare industry. Its primary function is to uphold the sterility of medical instruments, supplies, and equipment. In addition to preserving sterility, sterilization wrap serves as a protective shield, safeguarding healthcare staff from potential exposure to infectious materials. The significance of choosing the best sterilization wrap cannot be overstated, as it directly correlates with the safety and well-being of both staff and patients.

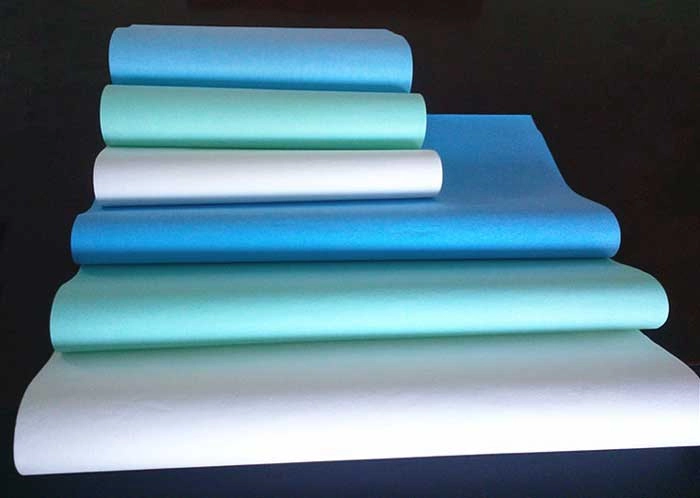

When embarking on the journey to select the ideal sterilization wrap, several crucial factors come into play. First and foremost, one must consider the sterilization method in use. Steam autoclaving stands as the most common sterilization process in healthcare facilities. Hence, it's essential to opt for a wrap specifically designed for this method, such as autoclave sterilization wrap. The size of the wrap is another pivotal factor, as it must adequately accommodate the items to be sterilized. Durability and the ability to withstand multiple rounds of sterilization round out the checklist, ensuring that the chosen wrap delivers on all fronts. Lastly, ease of use and the provision of the highest level of protection complete the criteria for selecting the best sterilization wrap.

Selecting the Best Sterilization Wrap

Choosing the finest Sterilization Wrap requires a meticulous evaluation of multiple aspects. The material used in the wrap, its size, strength, and intended use all deserve in-depth scrutiny. The material must exhibit the strength and durability needed to endure the rigors of sterilization processes, ensuring items remain uncontaminated. The size of the wrap should match the dimensions of the items to be sterilized, offering comprehensive coverage. Furthermore, an understanding of the intended use is essential, as various wraps cater to specific item types and processes. By taking all these factors into account, the journey to select the best Sterilization Wrap becomes a well-informed and strategic endeavor.

Types of Sterilization Wrap

Sterilization wrap can be categorized into two primary types: paper and plastic. Understanding the distinctions and benefits of each is pivotal for selecting the most suitable option for your healthcare facility.

Sterilization Kraft-paper: This single-layer kraft paper, or 1-ply kraft paper, is designed for one-time use, after which it is discarded. Mediwish kraft paper, made from 100% cellulose, is intended for packaging medical products before sterilization. This prevents secondary contamination of products with microorganisms after sterilization, as well as during subsequent transportation and storage until intended use.

Sterilization paper, also known as sterile paper or Autoclave paper: This cellulose-based sterilization wrap, commonly known as crepe paper, exhibits a finely creped surface. This texture, combined with additives, provides increased tensile strength when wet, crucial for resisting tearing during processing with hot, damp steam in an autoclave. Certain varieties are also made with the addition of synthetic fibers, creating soft crepe paper with improved drapeability.

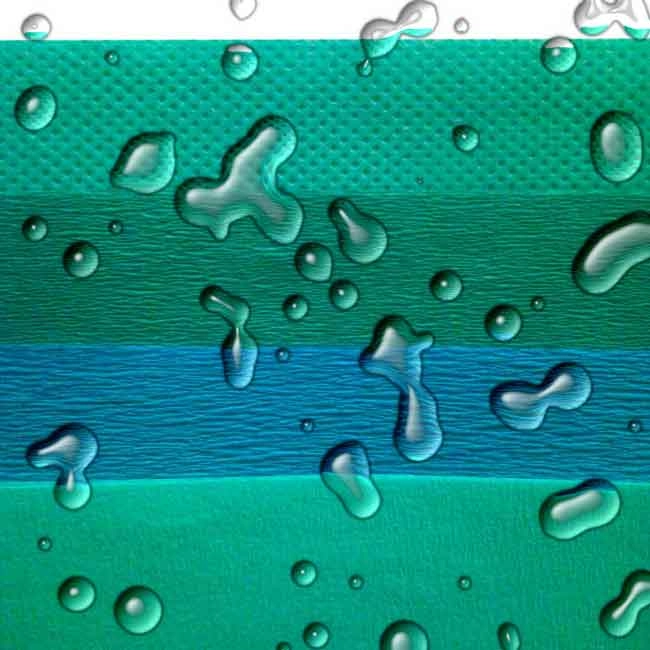

Plastic wrap: Comprising polypropylene, plastic sterilization wrap is known for its versatility in different sizes and styles. Multilayer nonwoven materials, such as SMMS (Spunbond-Meltblown-Meltblown-Spunbond), provide exceptional strength and durability. These materials, thanks to their meltblown layers, possess unique properties that spunbond materials lack.

SMS, or Spunbond Meltblown Spunbond, material consists of three meltblown layers of microscopic fibers, offering a consistent bacteriological barrier that maintains sterility. It comes in various colors and basis weights to cater to diverse user requirements. SMS materials are particularly recognized for their resistance to tears and stretching, moisture retention, and superior barrier protection. These properties make SMMS materials an excellent choice for packaging sterilization packages in the medical industry.The Affordability and Utility of Sterilization Wrap

Sterilization wrap is a favored choice for many healthcare facilities due to its affordability and user-friendliness. It is crafted from a variety of materials, including paper, plastic, and cloth. The primary function of sterilization wrap is to protect sterilized instruments and supplies from contamination, creating a physical barrier between sterile items and their surroundings. It is often employed alongside other sterilization techniques.

Despite its affordability and ease of use, sterilization wrap has its drawbacks. The wrap is not airtight, which means it may not offer complete protection against contamination. Moreover, it can tear or puncture easily, potentially compromising the sterilization process. Additionally, sterilization wrap is a single-use product, necessitating disposal after each use, which can add to the overall procedure cost.

Despite these limitations, sterilization wrap remains a popular choice in healthcare facilities, thanks to its cost-effectiveness and ease of use. It is a practical option, offering a critical layer of protection and maintaining sterility standards in the healthcare environment.

When it comes to selecting the best sterilization wrap for your healthcare facility, a thorough evaluation of material, size, strength, and intended use is essential. Mediwish® Sterilization Wrap stands out as a top choice, offering impressive strength, flexibility, and visualization support. Whether you opt for paper or plastic sterilization wrap, each has its unique advantages and applications. While sterilization wrap may have its limitations, it remains a valuable and practical option for maintaining sterility in healthcare settings.