Filter

By popularity (descending)

By popularity (descending)

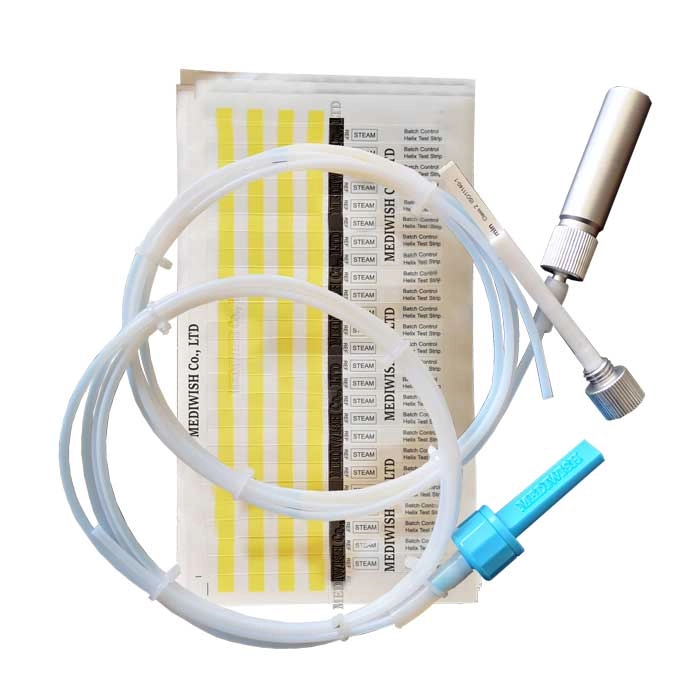

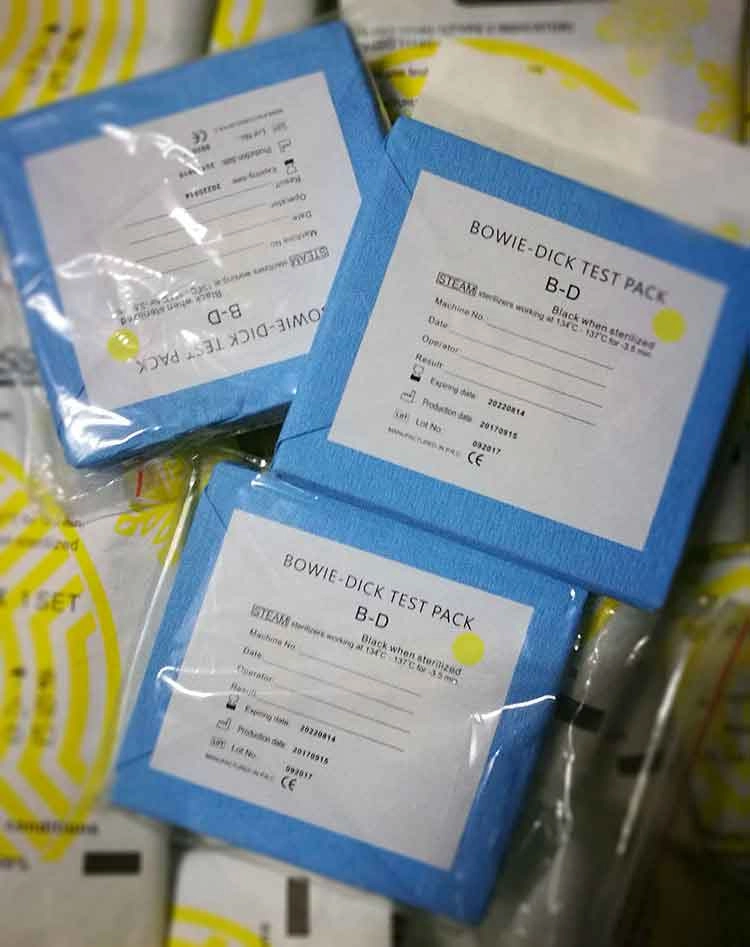

Sterility Assurance and Monitoring/Steam Sterilization/Bowie Dick Helix Test/PCD Autoclave

In stock

Art. 46536

USD$10.0/pc

USD$12.0/pc

Safe USD$2.0/pc

Add to cart

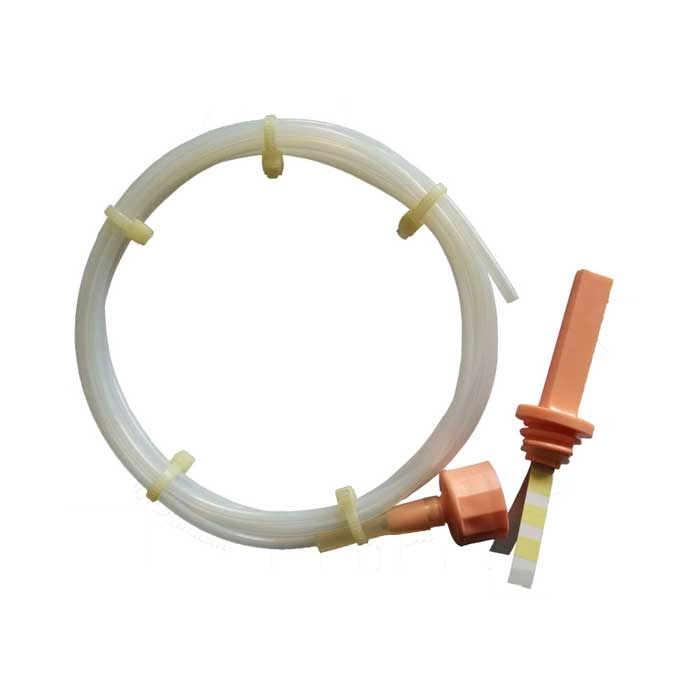

Sterility Assurance and Monitoring/Steam Sterilization/Bowie Dick Helix Test/PCD Autoclave

In stock

Art. 239761

USD $10 /set

USD $15.00 /set

Safe USD $ 5.00 /set

Add to cart

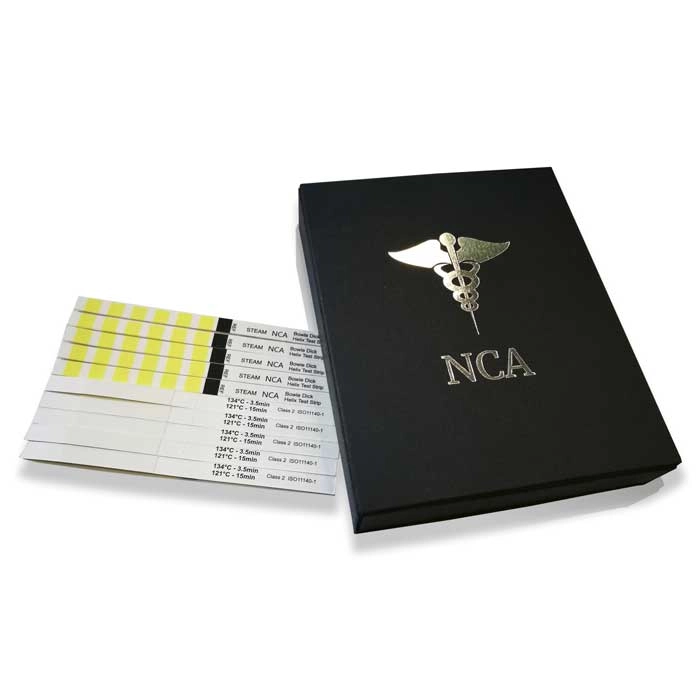

Bowie Dick Helix Test/Sterility Assurance and Monitoring/Steam Sterilization/PCD Autoclave

In stock

Art. 19763

USD $ 0.4 /piece

USD $ 0.7 /piece

USD $ 0.3 /piece

Add to cart