Plasma Sterilization: A Cutting-Edge Solution for Effective Decontamination

The Need for Effective Decontamination Methods

The importance of effective decontamination methods cannot be understated. The rise of antibiotic-resistant bacteria and the increasing number of healthcare-associated infections have posed significant challenges to the medical community. It is crucial to find innovative ways to sterilize medical equipment, instruments, and surfaces to ensure patient safety and prevent the transmission of infections. This is where plasma sterilization comes into play.

Understanding Hydrogen Peroxide Sterilization

One of the most widely used methods of plasma sterilization is hydrogen peroxide sterilization. This technique utilizes hydrogen peroxide gas plasma to eliminate microorganisms and achieve sterilization. The process involves the generation of low-temperature plasma from hydrogen peroxide, which then reacts with the microorganisms, rendering them inactive.

Hydrogen peroxide sterilization offers several advantages over other decontamination methods. Firstly, it is a dry sterilization process, which means there is no need for water or steam. This eliminates the risk of moisture-related damage to sensitive equipment. Additionally, hydrogen peroxide is a powerful oxidizing agent, making it highly effective in killing a wide range of microorganisms, including bacteria, viruses, and spores.

Advantages of Hydrogen Peroxide Gas Plasma Sterilization

The use of hydrogen peroxide gas plasma sterilization has several advantages that make it an attractive option for effective decontamination. Firstly, it is a rapid process, allowing for quick turnaround times and increased efficiency. Unlike traditional methods, plasma sterilization can achieve sterilization in a matter of minutes, reducing the waiting time for medical professionals.

Furthermore, hydrogen peroxide gas plasma sterilization is a safe and environmentally friendly method. The process does not produce any toxic byproducts, making it a sustainable choice for decontamination. It also eliminates the need for harmful chemicals, reducing the risk of exposure to healthcare workers and minimizing the impact on the environment.

How Plasma Sterilization Works

Plasma sterilization works by creating an environment where plasma, a partially ionized gas, interacts with the target microorganisms. The plasma contains highly reactive species, such as free radicals and charged particles, which have potent antimicrobial properties. When these species come into contact with the microorganisms, they disrupt vital cellular processes, leading to their inactivation and eventual death.

Plasma sterilization can be achieved through different methods, including low-pressure and atmospheric-pressure plasma. Low-pressure plasma sterilization is typically used for sterilizing medical instruments and equipment, while atmospheric-pressure plasma is suitable for decontaminating surfaces and larger areas. Both methods utilize the antimicrobial properties of plasma to achieve effective sterilization.

Applications of Plasma Sterilization in the Medical Field

Plasma sterilization has a wide range of applications in the medical field. It can be used to sterilize medical instruments, including surgical tools, endoscopes, and implants. The ability to achieve sterilization without the use of heat or water makes it particularly suitable for delicate and heat-sensitive equipment.

By implementing plasma sterilization, healthcare facilities can ensure a safer environment for both patients and healthcare workers.

Comparing Plasma Sterilization with Other Decontamination Methods

When comparing plasma sterilization with other decontamination methods, it becomes evident that plasma sterilization offers several unique advantages. Traditional methods such as autoclaving and chemical-based sterilization have their limitations. Autoclaving requires high temperatures and moisture, which can be detrimental to sensitive equipment. Chemical-based methods often involve the use of toxic substances, posing risks to both users and the environment.

In contrast, plasma sterilization provides a safe, efficient, and environmentally friendly alternative. The dry nature of the process eliminates the risk of damage to equipment, while the absence of toxic chemicals ensures the safety of healthcare professionals and the sustainability of the environment.

Challenges and Limitations of Plasma Sterilization

While plasma sterilization holds great promise, it is not without its challenges and limitations. One of the primary challenges is the need for specialized equipment to generate plasma. This can be costly and may limit the widespread adoption of plasma sterilization in certain healthcare settings.

Furthermore, plasma sterilization may not be suitable for all types of materials. Certain materials, such as those with complex geometries or porous surfaces, may not be effectively sterilized using plasma. It is important to consider the compatibility of materials with plasma sterilization before implementing the technique.

Future Developments in Plasma Sterilization Technology

As technology continues to advance, so does the potential for further developments in plasma sterilization technology. Researchers are exploring new ways to enhance the effectiveness and efficiency of plasma sterilization. This includes optimizing plasma generation techniques, developing new plasma sources, and improving the compatibility of materials with plasma sterilization.

Additionally, advancements in plasma diagnostics and monitoring systems are being made to ensure the effectiveness of the sterilization process. These developments will further solidify plasma sterilization as a cutting-edge solution for effective decontamination in the medical field.

Conclusion: The Promise of Plasma Sterilization for Effective Decontamination

In conclusion, plasma sterilization is a cutting-edge solution that holds great promise for effective decontamination in the medical field. With its rapid, safe, and environmentally friendly nature, plasma sterilization offers numerous advantages over traditional decontamination methods. While there are challenges and limitations to overcome, ongoing research and development in plasma sterilization technology will undoubtedly pave the way for even greater advancements in the future.

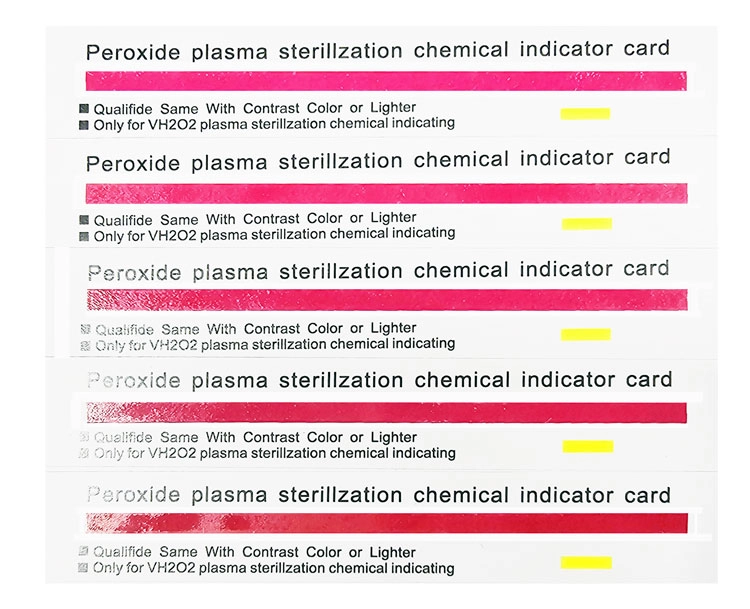

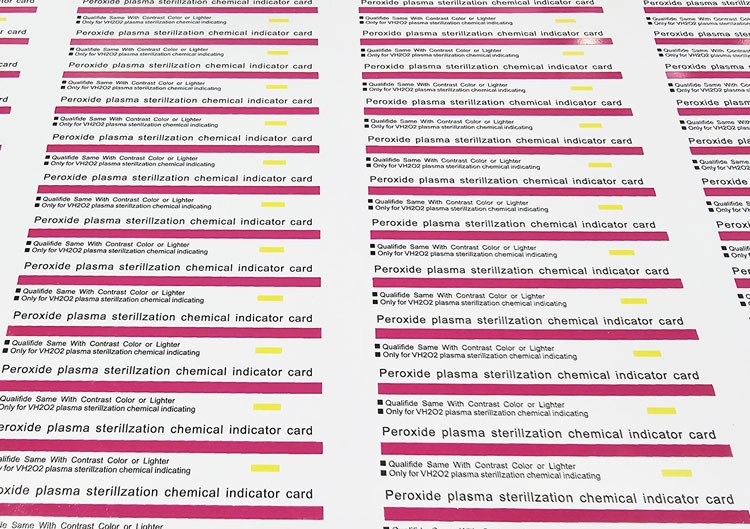

Mediwish Co., Ltd offers chemical indicators for control plasma sterilization. These indicators provide a visual confirmation of the sterilization process, ensuring that the desired level of decontamination has been achieved. By partnering with Mediwish Co., Ltd, healthcare facilities can enhance the effectiveness of plasma sterilization and maintain the highest standards of patient safety.