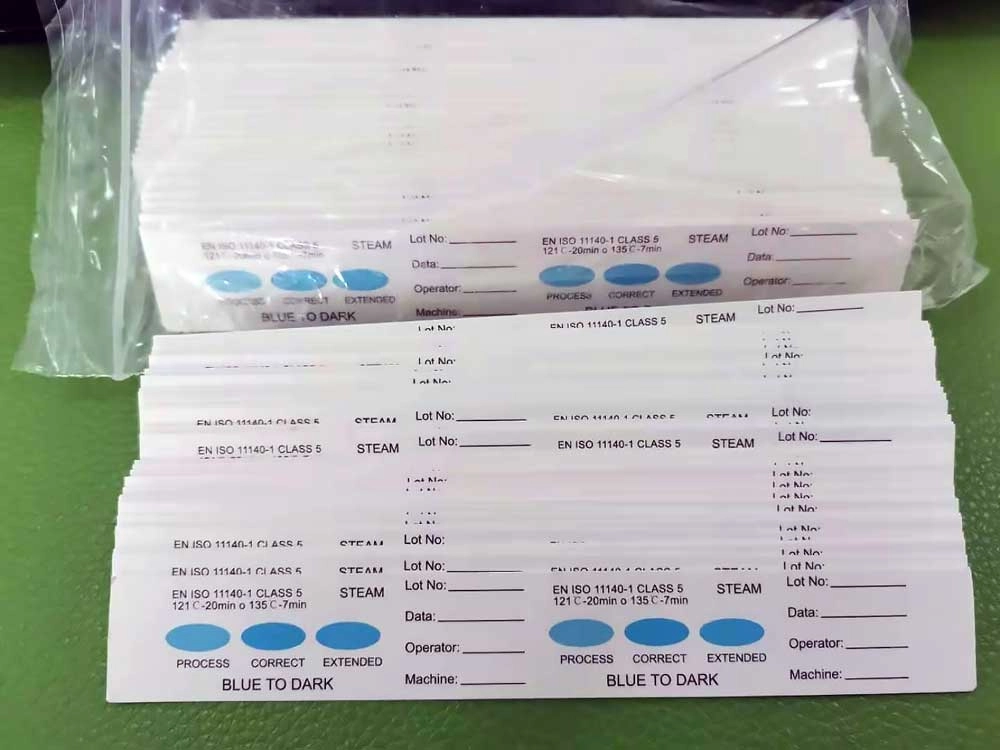

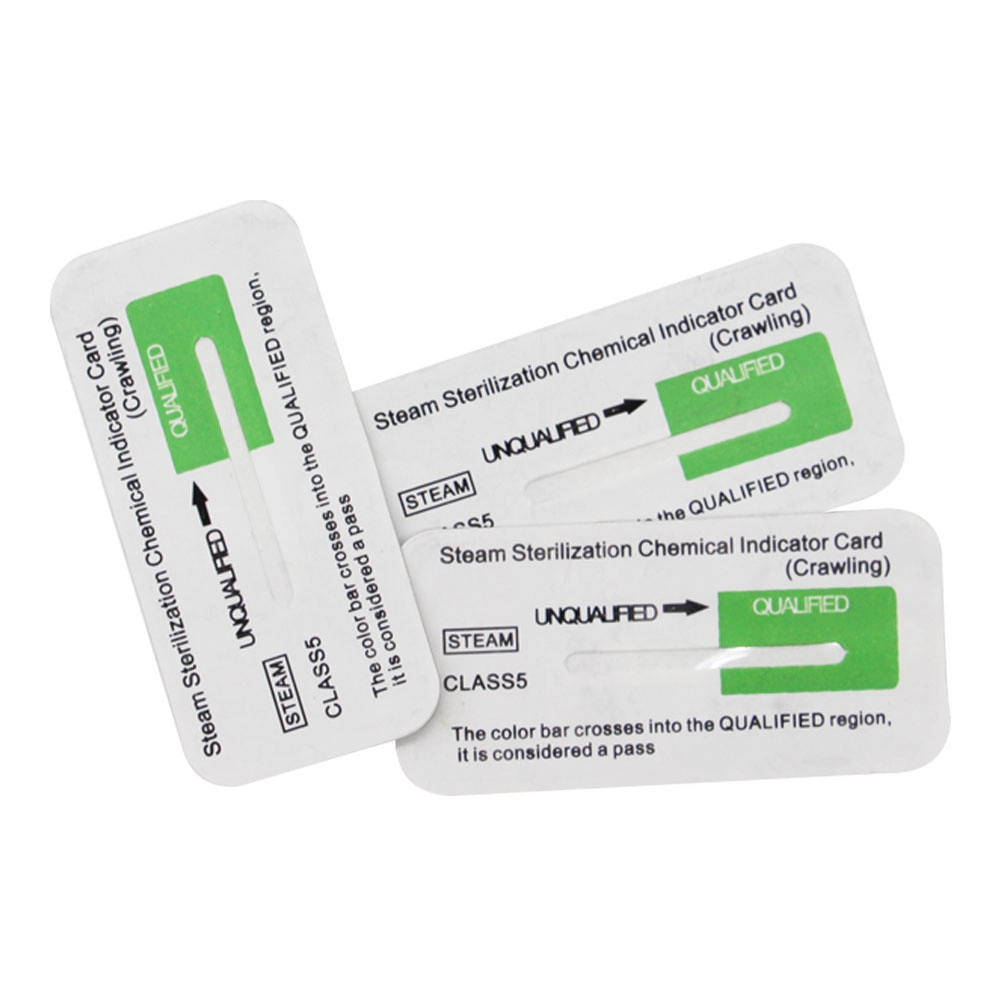

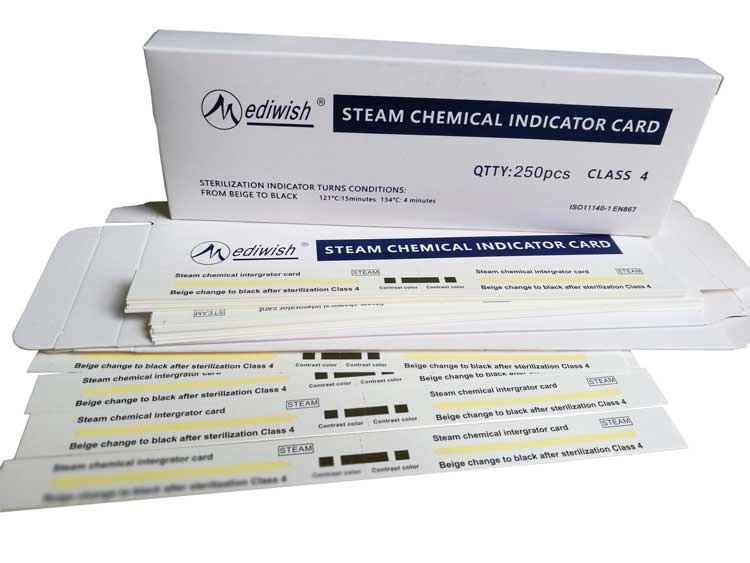

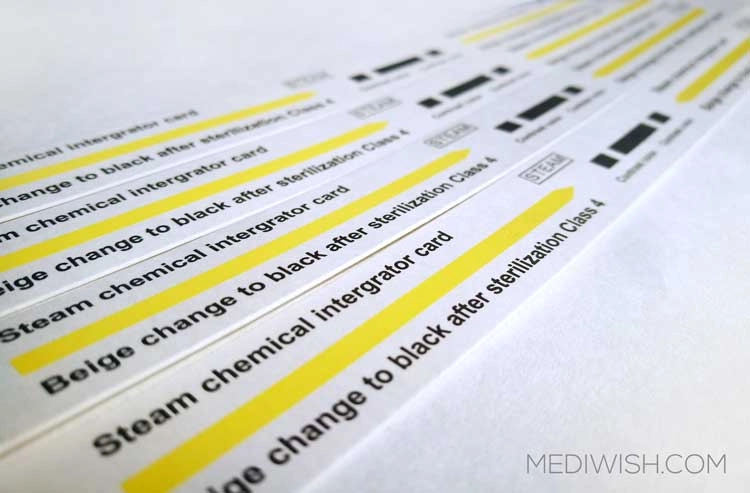

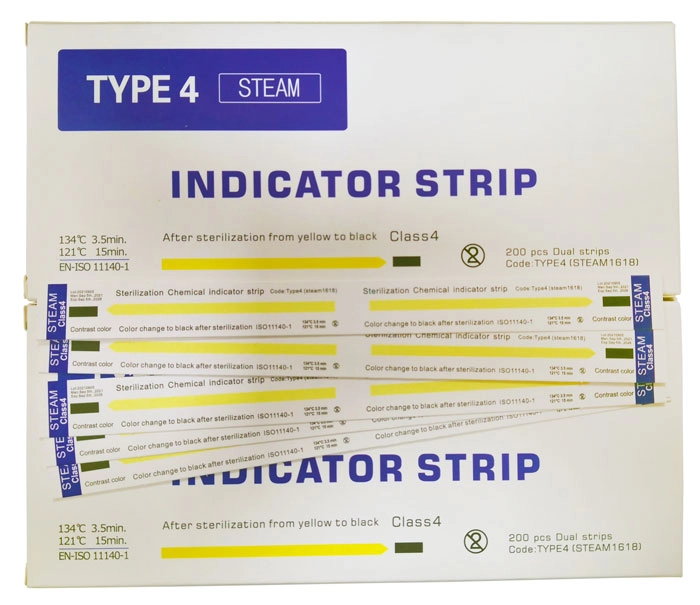

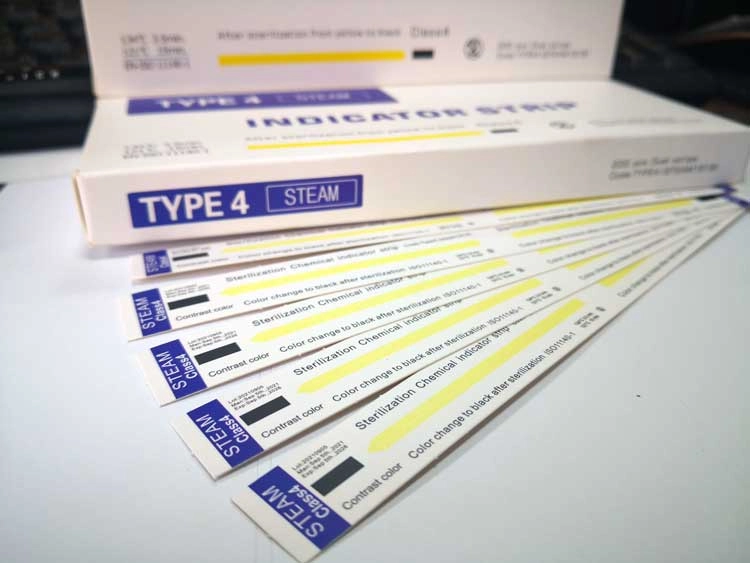

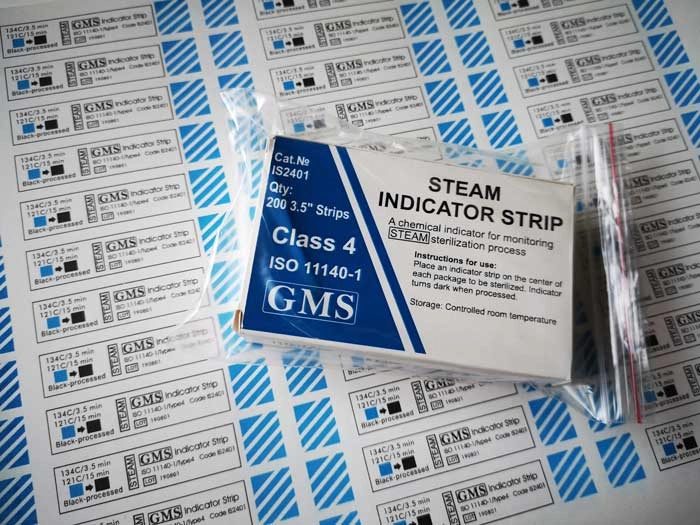

Indicators are strips of film and heat-resistant paper, they show whether sterilization has been carried out correctly or not. In the case of steam sterilization, indicators control the temperature, the period of its exposure, the saturation of water vapor; with the air method - the temperature and the duration of its exposure.

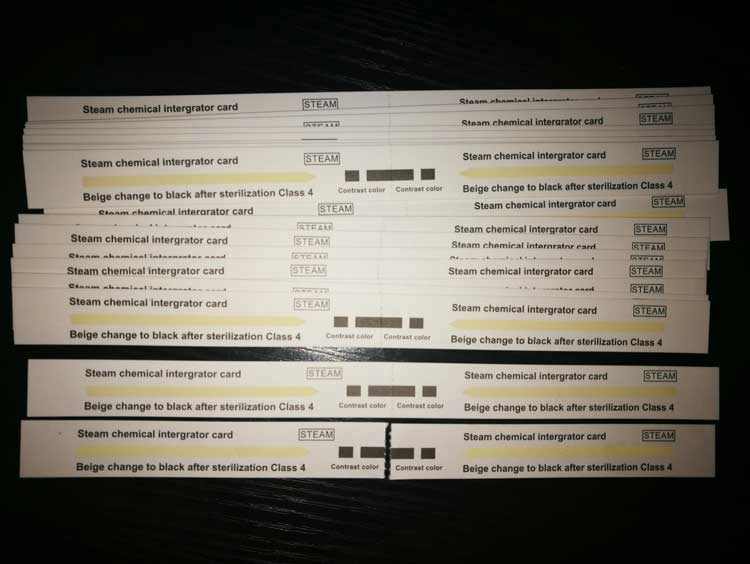

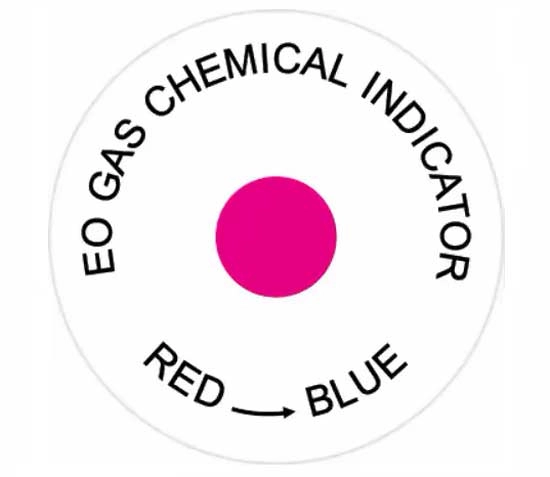

The indicator has a marking and two colored marks, one of which is an indicator, and the other is a comparison standard.

Sterilization indicators show whether the conditions in a steam autoclave process were sufficient to achieve a specific state of microbial inactivation.

Different Kinds of Sterilization Indicators

There are different kinds of sterilization indicators, according ISO 11140-1 classification. See them listed below:

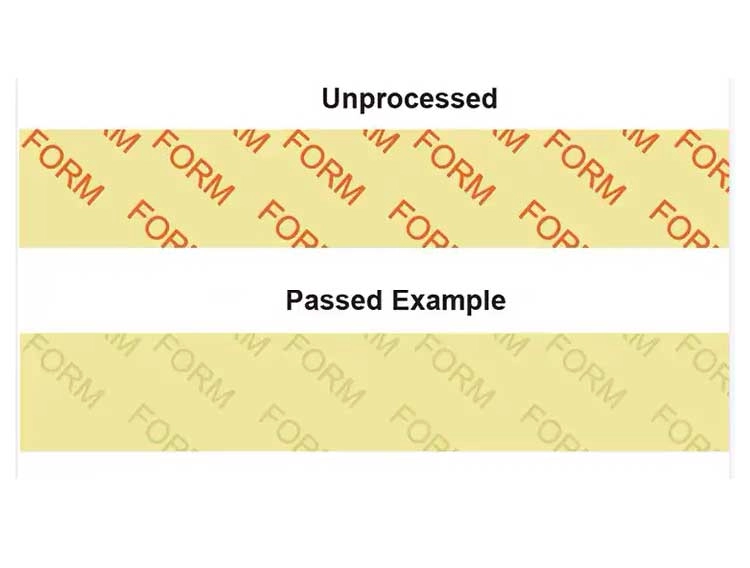

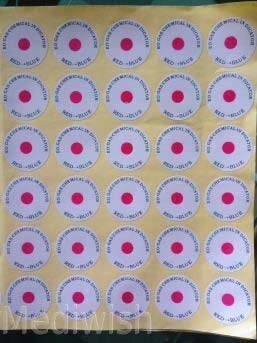

1. Process Indicators

These are the most basic type of chemical indicators; they are also called throughput indicators.

Process indicators are mostly used with people items to be sterilized. They are made to show that the item has passed through a sterilization process and to differentiate between non-processed and processed items. Examples of these indicators are tape and the indicators that are found on plastic-peel pouches or paper.

2. Indicators for Use in Specific Tests

They are also called specialty indicators. Indicators for use in specific tests are engineered for use in unique test processes.

For example, the indicators under this category include Bowie Dick products used in steam sterilizers. Indicators for use in specific tests show the presence of air in the steam sterilizing autoclave. A perfect test would show that air, which prevents the conditions needed for sterilization, has not evaporated during the sterilization process or has entered the chamber via an opening in the system.

Maintenance would need to be done on a steam sterilizer to overcome the presence of air in the autoclave during the sterilization process.

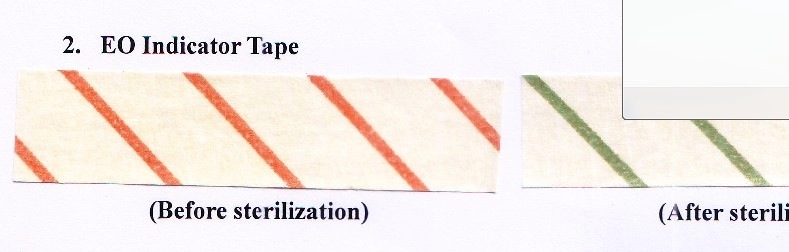

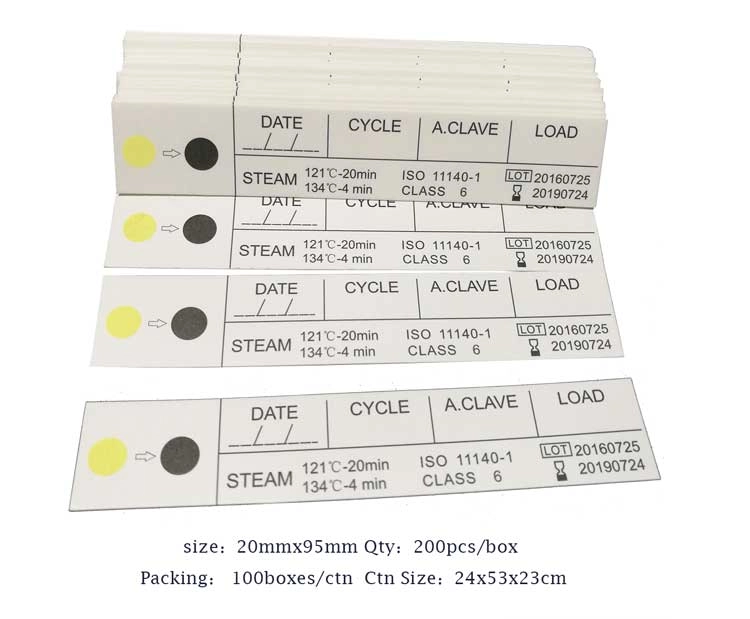

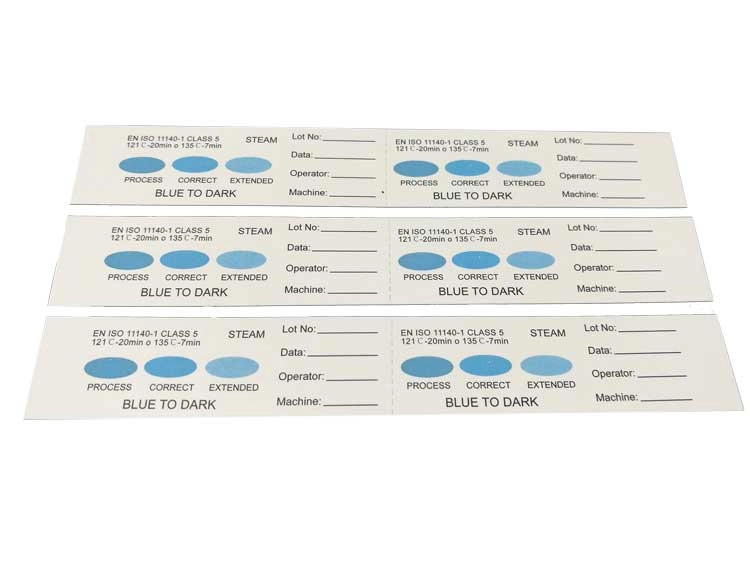

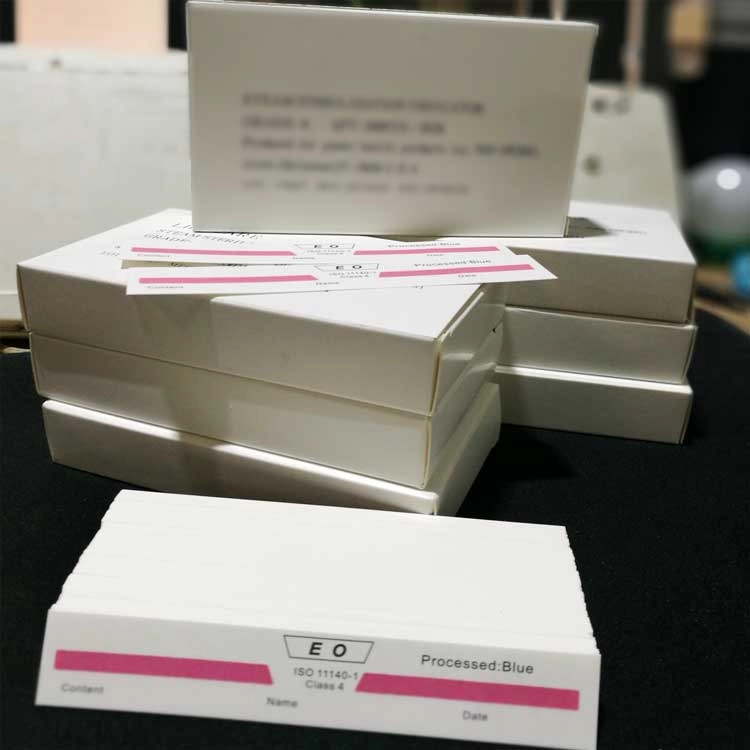

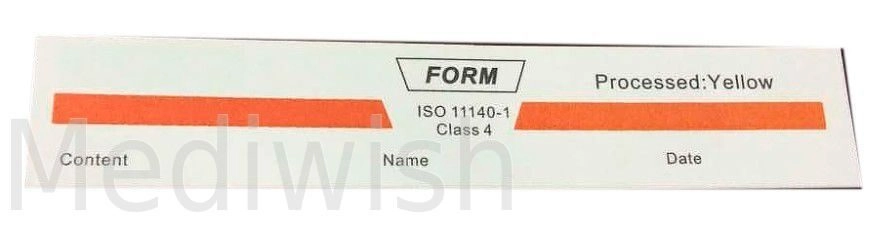

3. Multi-parameter Indicators

Multi-parameter indicators react to two or more critical parameters of the sterilization cycle and show exposure to the sterilization process at given values of the selected parameters. Temperature and time are examples of steam sterilization parameters. The concentration of ethylene oxide and time are selected for EO sterilization.

We have available several different products for use in sterilization monitoring. Talk to us today if you need help with any of these products.

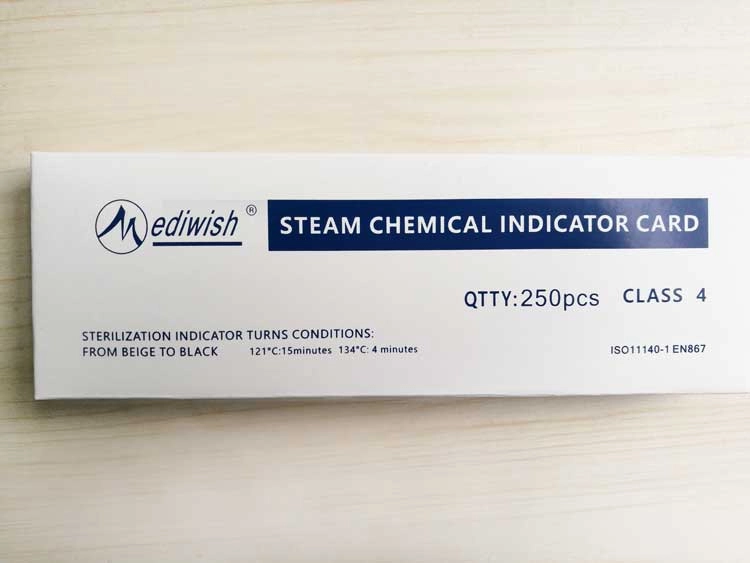

Mediwish Co., Ltd produce, supplies, sterilization indicators worldwide. If you have any questions about this article or would like to talk to us about sterilization indicators , please call our number, (+86) 55165557089, or email us at [email protected].