There's an invisible war fought every day in hospitals and laboratories against unseen assailants. These microscopic entities, known as germs, are combated with a variety of weapons. One such important weapon in this battle for hygiene and safety is the Sterilization Pouch. These seemingly inconspicuous items hold significant importance in maintaining the sterility of medical and laboratory equipment.

So, what are sterilization pouches exactly? This article aims to provide an insightful journey into the world of sterilization pouches.

Outline:

What Are Sterilization Pouches?

At their core, sterilization pouches are specialized packaging designed to hold items that need to be kept in a sterile environment. They serve a fundamental role in various industries, especially healthcare, where they're indispensable for storing surgical instruments, bandages, or other materials that need to be shielded from microbes.

Their purpose transcends beyond mere storage. When used correctly, these pouches can maintain the sterility of the packaged item for a prolonged period. This capability is crucial in various settings, such as operating rooms or labs, where exposure to contamination can have serious repercussions. Thus, these pouches play an instrumental role in infection control.

The Science Behind Sterilization Pouches

Sterilization is more than just a rigorous cleaning process. It's a scientific method that involves killing or removing all forms of life and other biological agents, including bacteria, viruses, spore forms, fungi, and prions. What role do sterilization pouches play in this process? They act as a barrier against microbes, ensuring the enclosed items remain sterile post the sterilization process until their usage.

The Concept of Sterilization

Sterilization is achieved through various methods such as heat, chemicals, irradiation, high pressure, and filtration. In a medical context, sterilization aims at eradicating all forms of life from the medical equipment to prevent infection spread during procedures. Given the diversity of methods used for sterilization, the pouches must be made of materials that can withstand these processes without compromising their integrity.

How Do Sterilization Pouches Work?

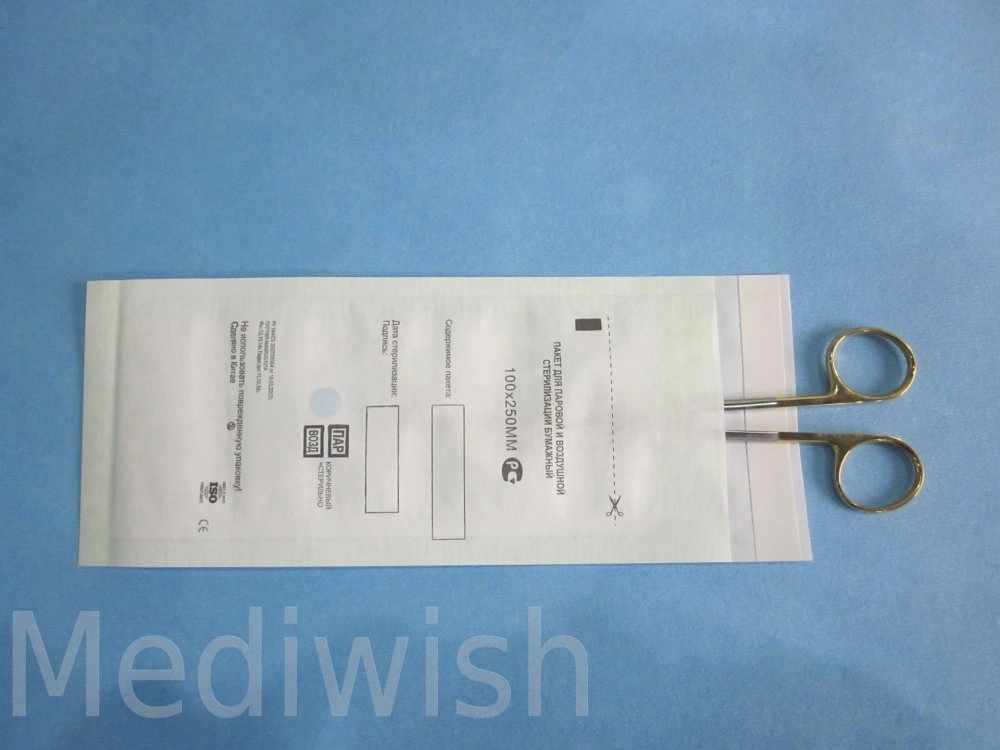

The working principle of sterilization pouches relies on their ability to withstand the sterilization process while maintaining a sterile internal environment. Their design often includes a transparent side to visually inspect the contents and a porous side that allows the sterilization agent (like steam or Ethylene Oxide gas) to permeate the pouch and sterilize the contents. After the sterilization process, the sterile bags act as a physical barrier, keeping the sterilized items free from contamination till the moment of use.

The following sections will go into more detail about the types of sterilization pouches available in the market, the materials used in their construction, and the indicators that inform us about the success of the sterilization process. We'll also discuss how to correctly use these pouches, their comparison with reusable containers, and the regulations that govern their manufacture and use.

So, stay tuned and keep reading to expand further your understanding of sterilization pouches and their integral role in maintaining hygiene and safety in various industries, especially healthcare.

Types of Sterilization Pouches

The two primary categories of sterilization pouches are Self-Seal Pouches and Heat-Seal Pouches.

Self-Seal Pouches

Self-seal pouches are designed with a built-in adhesive strip that creates a secure seal when folded and pressed. The convenience of self-sealing eliminates the need for a heat sealer machine, making these pouches a popular choice in small healthcare units, dental clinics, and tattoo parlors. However, ensuring the adhesive strip is free from contamination before sealing is crucial to maintain the sterile environment within.

Heat-Seal Pouches

On the other hand, heat-seal pouches require a separate machine to create a seal. These pouches are ideal for extensive healthcare facilities, as the heat-sealer offers a consistent and robust seal, enhancing the safety of the sterilization process. While the initial investment for the sealing machine might be higher, the long-term benefits include increased reliability and effectiveness.

Materials Used in Sterilization Pouches

Different materials are used to manufacture sterilization pouches, the most common being Plastic and Paper.

Plastic Pouches

Plastic pouches, specifically those made from medical-grade polyester or polypropylene, are durable and resistant to tears and punctures. They are impermeable to bacteria and liquids, making them ideal for maintaining sterility. The transparent plastic side also allows for easy visual inspection of the pouch contents.

Paper Pouches

On the other hand, paper pouches are appreciated for their eco-friendly nature, as they decompose more readily than their plastic counterparts. Pouches for sterilization are produced from medical-grade waterproof bleached craft paper. These pouches are designed to allow sterilization agents to permeate and effectively sterilize the contents. They offer a cost-effective solution but are more prone to tears and punctures.

These pouches play a vital role in protecting sterilized items from contamination. Still, it's equally important to understand whether the sterilization process was successful in the first place. This understanding brings us to the concept of sterilization indicators.

Understanding Sterilization Indicators

Sterilization indicators are integral to sterilization pouches. They provide visual confirmation that the contents of the pouch have been exposed to the sterilization process. The indicators could be Chemical Indicators or Biological Indicators.

Chemical Indicators

Chemical indicators are substances that undergo an apparent color change when exposed to certain conditions during sterilization. They are usually printed on the pouch and serve as an immediate, though not absolute, verification that the pouch has undergone sterilization. However, they do not guarantee that the sterilization process was successful and all microbes were killed.

Biological Indicators

Biological indicators, on the other hand, use living spores, usually of the bacteria Geobacillus stearothermophilus. These spores are among the most heat-resistant, and their eradication assures the elimination of other potential microbes. After sterilization, these indicators are incubated. If the spores have been killed, no bacterial growth occurs, confirming the success of the sterilization process. While more reliable than chemical indicators, biological indicators are time-consuming and not typically used on every pouch.

Understanding the sterilization process and indicators is important, but it is equally crucial to know how to correctly use these pouches. Let's delve into that next.

Proper Usage of Sterilization Pouches

Understanding the correct way to pack and use a sterilization pouch is vital for ensuring the sterility of the items contained within. Here's a step-by-step guide:

How to Correctly Pack a Pouch

- Selection: Choose a pouch that is appropriately sized for the items to be sterilized. The bag should be large enough to contain the things without stressing the seals.

- Packing: Place the items inside the pouch. Ensure not to overload the bag as it can lead to ineffective sterilization and potential tear.

- Sealing: Seal the pouch as per the type - self-seal or heat-seal.

- Sterilization: Put the pouch in a sterilizer. Ensure the pouch's paper side faces the sterilizer's chamber and the plastic side faces the door.

- Storage: Once sterilized, store the pouches in a clean, dry, and dust-free area.

Sterilization Process

The sterilization process largely depends on the sterilization equipment available. The standard sterilization methods include steam sterilization (autoclaving), dry heat sterilization, and Ethylene Oxide sterilization. The sterilization process should be chosen based on the nature of the items to be sterilized and the pouch material.

Note: It's crucial to remember that the pouches should be opened just before use to prevent contamination.

However, sterilization pouches are not the only method for maintaining sterility. Reusable containers are an alternative worth considering.

Sterilization Pouches vs. Reusable Containers

While sterilization pouches have been our primary focus, it's worth noting that they have a counterpart – reusable sterilization containers. Comparing the two can offer a better understanding of their strengths and weaknesses.

Pros and Cons

Sterilization Pouches:

Pros: These are cost-effective and disposable, reducing the risk of cross-contamination. Their transparency allows for easy visual inspection of the content.

Cons: Their disposable nature may raise environmental concerns. Additionally, they require careful handling to prevent tears and punctures.

Reusable Containers:

Pros: They are environmentally friendly and durable. Over time, they could be more cost-effective due to repeated usage.

Cons: The initial investment is high. They require rigorous cleaning after each use, which can be labor-intensive and time-consuming.

Making an Informed Choice

The choice between sterilization pouches and reusable containers depends mainly on the specific requirements of the healthcare facility, available resources, the volume of items to be sterilized, and the environmental impact considerations.

The following crucial facet to consider is the regulatory landscape governing sterilization pouches' production and usage.

Regulatory Aspects of Sterilization Pouches

Regulations are crucial in maintaining the standards of sterilization pouches, ensuring their quality, and verifying their efficiency in maintaining sterility.

FDA Regulation

In the United States, sterilization pouches are considered Class I medical devices. This means they are subject to Food and Drug Administration (FDA) regulations. Manufacturers are required to register their establishments and list their devices with the FDA. They must also follow Quality System regulations, which include good manufacturing practices.

ISO Standards

Internationally, the ISO (International Organization for Standardization) has established standards for sterilization pouches. Notably, ISO 11607-1 provides requirements and test methods for materials, design, manufacture, and packaging performance meant for terminally sterilized medical devices.

CE Marking

In the European Union, sterilization pouches must carry a CE (Conformité Européene) marking, indicating compliance with EU safety, health, and environmental requirements. This compliance is judged based on tests performed by a notified body.

Regulatory compliance is critical in ensuring the safety and efficacy of sterilization pouches. This also means users can trust these devices to provide the sterility required in their practice.

Let's conclude our discussion with some frequently asked questions.

Frequently Asked Questions

What is the shelf life of sterilized pouches?

The shelf life of sterilized pouches depends on the pouch material's quality, the storage conditions, and the packaging practices. Some sterilized pouches can maintain sterility for up to six months or even five years when stored under ideal conditions- clean, dry, and away from sunlight. However, following the manufacturer's guidelines for specific products is best.

Can sterilization pouches be reused?

Sterilization pouches are designed for single use and should not be reused. Reusing the pouches can compromise the sterility of the contents, increasing the risk of contamination and infection. Moreover, regulatory bodies such as the FDA strongly discourage the reuse of sterilization pouches.

Why are sterilization pouches transparent on one side?

The transparent side of the pouch enables users to visually inspect the contents without having to open the pouch. This design helps maintain the contents' sterility until the moment of use.

Can any heat-resistant bag be used as a sterilization pouch?

No, not all heat-resistant bags can function as sterilization pouches. Sterilization pouches are designed with specific materials to resist different sterilization processes and maintain sterility. They also carry sterilization indicators to show that the sterilization process has been carried out.

What happens if a sterilization pouch is punctured or torn?

If a sterilization pouch is punctured or torn, it can no longer maintain a sterile environment for the contents. Any breach in the pouch can allow microbes to contaminate the sterilized contents. Therefore, any pouch with even a minor tear or puncture should not be used.

Conclusion

To sum up, sterilization pouches play a critical role in various industries, particularly in healthcare settings, where maintaining the sterility of instruments is paramount. Understanding their types, the materials used, their proper usage, and the regulations governing them are all essential to ensuring safe and effective use. With their help, we can keep our tools clean, secure, and ready for use, furthering the goal of infection prevention and control.

Global Market of Sterilization Pouches

The global market for sterilization pouches has seen steady growth over the years, driven by the increasing awareness about infection control, growing healthcare infrastructure, and the rising number of surgeries worldwide. As per market reports, the industry is expected to continue its upward trajectory in the coming years.

Market Size and Growth

The global market for sterilization pouches was valued at $336.1 million in 2020 and is projected to reach $448.5 million by 2027, growing at a CAGR of 4.2% from 2021 to 2027 (source: Allied Market Research). North America holds the largest share of the market, followed by Europe. Still, the fastest growth in the Asia-Pacific region is expected, driven by increasing healthcare expenditure, rapid industrialization, and medical tourism.

Driving Factors

Several factors are driving the growth of this market. The rising incidences of hospital-acquired infections (HAIs) have led to an increased emphasis on sterilization in healthcare settings. The growing number of surgeries and expanding healthcare infrastructure, particularly in developing countries, are other significant factors. Furthermore, the COVID-19 pandemic has increased demand for sterilization pouches due to heightened hygiene standards.

Major Players in the Industry

The global sterilization pouch market is highly competitive, with numerous international and regional players. Some of the key players in this industry include:

- 3M Company: An American multinational conglomerate corporation, 3M produces a variety of sterilization pouches, including self-seal and heat-seal pouches.

- Cardinal Health: This American multinational healthcare services company offers sterilization pouches as part of its extensive healthcare product range.

- Medline Industries: A private American healthcare company, Medline manufactures and distributes various healthcare supplies, including sterilization pouches.

- Steris Corporation: Steris is a leading provider of infection prevention and surgical products and services, including sterilization pouches.

Trends and Predictions

Looking ahead, several trends are likely to shape the sterilization pouches market:

Increased Focus on Sustainability

With growing awareness about environmental issues, there is an increasing demand for sustainable and biodegradable sterilization pouches. Companies are investing in R&D to develop eco-friendly materials that maintain sterility effectively.

Advancements in Sterilization Technologies

The rise in innovative sterilization technologies, such as low-temperature sterilization, is expected to spur the development of new types of sterilization pouches designed to withstand these processes.

Regulatory Changes

As regulations around medical devices and sterilization continue to evolve, manufacturers must adapt their products to comply with new standards, which could impact the market dynamics.

To sum up, the sterilization pouches market is on a positive growth trajectory, influenced by numerous factors, including technological advancements, regulatory changes, and rising healthcare standards globally.

Challenges in the Sterilization Pouches Market

Despite the positive growth trajectory, the sterilization pouches market faces several challenges that could hamper its progress.

Environmental Concerns

Most sterilization pouches are single-use and made from non-biodegradable materials, which raises serious environmental concerns. These concerns could result in stricter environmental regulations, which in turn could challenge the market's growth.

High Competition

The sterilization pouches market is highly competitive, with numerous players offering similar products. This high level of competition can lead to price wars and reduced manufacturer profit margins.

Emerging Opportunities

While challenges exist, they are often accompanied by opportunities. Two potential growth areas could be the development of sustainable pouches and the expansion into emerging markets.

Sustainable Sterilization Pouches

As mentioned earlier, the demand for eco-friendly sterilization solutions is growing. Manufacturers that can develop biodegradable or reusable sterilization pouches could seize a significant market opportunity.

Emerging Markets

While developed markets like North America and Europe currently dominate the sterilization pouches market, emerging economies in Asia-Pacific and Latin America offer untapped potential. Increasing healthcare expenditure and the growth of medical tourism in these regions present lucrative opportunities for market players.

Conclusion

The sterilization pouches market is complex and dynamic, shaped by various factors, including technological advancements, evolving regulations, and changing consumer demands. Despite facing environmental concerns and high competition, the market shows promise, particularly for manufacturers that can innovate and adapt to changing market needs. As we move forward, the focus will likely continue to be on developing more sustainable sterilization solutions and capitalizing on growth opportunities in emerging markets.

History and Creators of Sterilization Pouches

Understanding the history and creators of sterilization pouches can provide valuable context and perspective on their development and usage over time.

Early History of Sterilization

The concept of sterilization traces back to the late 19th century, following Louis Pasteur's germ theory of disease, which showed that microorganisms cause diseases. Subsequently, methods of sterilization were developed to kill these microorganisms.

Initial methods were rudimentary, typically involving moist heat (steam) or dry heat. Items to be sterilized were wrapped in cloth or placed in metal containers before sterilization, which did not guarantee complete sterility and protection against recontamination.

Development of Sterilization Pouches

The invention of sterilization pouches, as we know them today, was a step forward in the evolution of sterilization methods. They were designed to withstand the sterilization process and maintain the sterility of the instruments until the point of use.

It's hard to attribute the invention of sterilization pouches to a specific individual or company because their development was a gradual process involving many contributors. Early sterilization pouches were made of cloth and later of paper, evolving into the paper-plastic bags commonly used today.

One notable player in this field was Johnson & Johnson, manufacturing healthcare products since the 1880s and introducing many sterilization products, including pouches. Today, many companies worldwide manufacture sterilization pouches, including 3M, Cardinal Health, Medline Industries, and Steris Corporation, among others.

The exact timeline of when sterilization pouches were first created must be clarified. However, their widespread usage began in the mid-20th century with the advent of modern healthcare and surgical practices.

Modern Sterilization Pouches

Today's sterilization pouches are designed with features such as self-sealing, sterilization indicators, and different layers of materials to maintain sterility. These enhancements have made sterilization pouches more reliable and convenient, contributing to their widespread adoption across various industries, primarily healthcare.

Sterilization pouches will likely continue evolving, driven by technological advancements, environmental considerations, and changing healthcare needs.

Evolution of Sterilization Pouches

Over the years, sterilization pouches have evolved significantly to meet the changing needs of various industries, particularly healthcare.

Material Innovations

Early sterilization pouches were made of cloth or paper, which did not guarantee optimum sterility and offered minimal protection against recontamination. Modern pouches are made from a combination of materials like medical-grade paper with not less then 60 gram/m2 and plastic multylayer composite film, such PE/CPP, PE/PA etc. The paper side allows for effective penetration of the sterilization agent. At the same time, the transparent plastic film enables visual inspection of the contents without opening the pouch.

Self-Sealing and Sterilization Indicators

Innovations such as self-sealing and sterilization indicators have made sterilization pouches more user-friendly and reliable. Self-sealing pouches eliminate the need for sealing machines, thereby improving efficiency. At the same time, sterilization indicators change color to visually confirm that the contents have undergone the sterilization process.

Impact of Sterilization Pouches

The advent and evolution of sterilization pouches have profoundly impacted various sectors.

Healthcare

In healthcare, sterilization pouches have transformed infection control practices. They have made it possible to maintain the sterility of surgical and dental instruments until the point of use, significantly reducing the risk of healthcare-associated infections.

Other Industries

Apart from healthcare, sterilization pouches are also used in other sectors, such as pharmaceuticals, food and beverages, and cosmetics. They ensure the sterility of various items, contributing to consumer safety.

The Future of Sterilization Pouches

Looking ahead, sterilization pouches are likely to continue evolving. Potential development areas include using sustainable materials to reduce environmental impact and incorporating advanced sterilization indicators for improved accuracy. Moreover, with the COVID-19 pandemic highlighting the importance of sterilization, the demand for sterilization pouches is expected to grow.

In conclusion, sterilization pouches, while seemingly simple, are sophisticated products that play a critical role in ensuring sterility and preventing infections. Understanding their history, evolution, and impact can help us appreciate their importance and potential for future development.

Uses of Sterilization Pouches

Sterilization pouches are integral to a wide range of industries due to their ability to maintain the sterility of tools and products. Here are some key areas of application:

Medical and Dental Practices

In medical and dental practices, sterilization pouches are used to store surgical and dental instruments after they have been sterilized. They keep these tools sterile until they are needed, which helps prevent patient infections.

Pharmaceutical Industry

The pharmaceutical industry uses sterilization pouches to ensure the sterility of certain products, such as surgical gloves and other equipment that need to be sterile when used.

Cosmetic Industry

In the cosmetic industry, sterilization pouches are used for tools like tattooing and piercing needles to prevent skin infections.

Food and Beverage Industry

While less common, the food and beverage industry uses sterilization pouches for specific tools and equipment that need to be sterile to ensure the safety of the products.

Types of Sterilization Pouches

Different types of sterilization pouches are designed for specific sterilization methods and needs. Here are some of the common types:

Heat-Seal Sterilization Pouches

Heat-seal pouches require a heat sealer to seal the pouch after the item is placed inside. These pouches are durable and provide a high level of protection against contamination.

Self-Seal Sterilization Pouches

Self-seal pouches have a built-in adhesive seal that doesn't require a heat sealer. This makes them quicker and easier to use, ideal for situations where speed is crucial.

Tyvek Sterilization Pouches

Tyvek pouches are made from a synthetic material that is highly resistant to microbial penetration. They are often used to sterilize medical devices, as they can withstand all standard methods.

In conclusion, sterilization pouches are an essential part of modern healthcare and other industries, and they come in various types to suit different needs. Their role in maintaining sterility and preventing infections cannot be overstated.