Why ETO Indicator Tapes Matter: Ensuring Patient Safety and Compliance

EO sterilization:

- Used for medical devices and equipment sensitive to heat or moisture.

- Employs ethylene oxide gas to kill microorganisms, including bacteria, viruses, and spores.

- Essential for ensuring patient safety in healthcare settings.

Accurate monitoring:

- Verifies proper exposure to EO gas sterilization during sterilization cycle.

- Prevents under-sterilization (potentially leading to infections) and over-exposure (equipment damage).

- Ensures compliance with regulatory requirements and safety guidelines.

In short:

Accurate monitoring with ETO indicator tapes is vital for guaranteeing the effectiveness and safety of EO sterilization, protecting patients and upholding regulatory standards.

Understanding ETO Indicator Tapes: Your Essential Guide

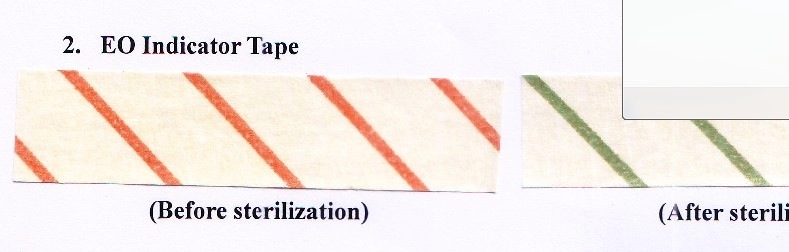

Definition type 1 chemical indicator and their function:

Type 1 chemical indicators are self-contained devices that undergo a visible change (e.g., color change) when exposed to specific sterilization conditions. In the context of ETO sterilization, they are classified as single-parameter indicators, meaning they respond to one crucial parameter like ethylene oxide concentration.

Function:

Their primary function is to provide a visual confirmation that the minimum required concentration of EO gas was present during the sterilization cycle. This helps ensure proper microbial inactivation and patient safety.

Limitations:

It's important to remember that type 1 indicators do not:

- Provide information about other critical parameters like temperature, humidity, or time.

- Guarantee complete sterility or the effectiveness of sterilization.

- Replace biological indicators, which are considered the gold standard for sterility assurance.

Overall:

Type 1 chemical indicators offer a simple and cost-effective way to visually monitor ETO sterilization for the presence of minimum EO concentration. However, they should be used in conjunction with other monitoring methods for a more comprehensive assessment of sterilization effectiveness.

Key features:

|

Specification |

Details |

|---|---|

| Roll size | Convenient sizes like 50m x 18mm, 50m x 24mm, etc. cater to various usage needs. |

| EO gas chemical indicator | Color change (pink to orange) provides clear visual confirmation. |

| Sterilization tape indicator | printed on surface with "zebra" pattern. |

| Adhesion Strength | Secure attachment to woven, non-woven fabrics, and sterilization wraps |

| Elongation | ≥7% |

| Tensile Strength | ≥8.0 N/25mm |

| Adhesion Strength to Steel | ≥10N/25mm |

| Compatible Temperature Range | 37ºC - 54ºC |

| Color Sensitivity | Ensures reliable color change under specified EO conditions: |

| Conditions 1: 600 mg/l EO, 60% RH, 54ºC, 20 minutes | |

| Conditions 2: 600 mg/l EO, 60% RH, 37ºC, 25 minutes |

Intended Use: Evidence Control ETO Sterilization Monitoring in Gas Autoclave

This ETO indicator tape is specifically designed for providing evidence control and visual confirmation of proper sterilization exposure in ETO sterilization chambers. It functions as a single-parameter eo indicator, confirming the presence of the minimum required ethylene oxide concentration during the sterilization cycle.

This information clarifies the specific purpose of the ETO indicator tape within the context of

ETO sterilization processes. It emphasizes its use as a monitoring tool within

designated equipment (EO gas sterilizer) and highlights its role in providing documented

evidence of proper exposure.

Performance You Can Trust: Key Specs and Testing

· Color change threshold:

· Color change in 20 minutes, if ethylene oxide gas concentration in sterilization chambler present 600 mg/liter, humidity inside at least 60% and temperature 54ºC; Delta E (CIELAB ΔE)≥25 [4]

· Color change in 25 minutes, if ethylene oxide gas concentration in sterilization chambler present 600 mg/liter, humidity inside at least 60% and temperature 37ºC; Delta E (CIELAB ΔE)≥25 [4]

· Color difference CIELAB color space [3]:

· Temperature range: Verify compatibility with your sterilization cycle's temperature range.

· Independent testing: Look for data from reputable laboratories supporting performance claims.

- SGS report.

- ETO Indicator Tape compliant with ANSI/AAMI ST79 [1] and ISO 11140-1standards.

Safety First: Heavy Metal-Free and Material Compatibility

Heavy metal-free: EO indicator tape complying with regulations like ANSI/AAMI ST79 and ISO 11140-1, Class 1.

Material compatibility: Verify safe use with sterilization wrap materials in your facility.

Ease of Use: Adhesion strength: Ensure secure attachment throughout the sterilization process without residue upon removal.

Surface treatment: Opt for easy writing on the gas tape for clear identification and documentation.

User-Friendly Features for Streamlined Workflow

Secure Attachment and User-Friendly Features:

Adhesion Strength:

- This ETO indicator tape boasts strong adhesion that securely attaches to a variety of materials commonly used in sterilization, such as woven and non-woven fabrics, sterilization wraps, and even steel.

- This ensures the gas sterilization tape remains firmly in place throughout the entire sterilization cycle without peeling or falling off, guaranteeing accurate monitoring and preventing potential contamination.

Surface Treatment:

- The ethylene oxide indicator tape features a specially treated surface that allows for easy and clear writing.

- This facilitates crucial documentation by enabling you to readily mark essential information like lot numbers, sterilization cycle details, or dates directly on the sterilization indicator tape.

- Clear and accurate labeling promotes organization and traceability within your sterilization processes.

Additional Features:

- Pre-printed lot numbers: This option eliminates the need for manual labeling, saving time and reducing the risk of errors.

- Sterilization cycle indicators: Pre-printed icons or indicators on the tape can easily identify specific sterilization cycles, simplifying record-keeping and ensuring the right tape is used for each process.

Benefits of Strong Adhesion and User-Friendly Features:

- Reliable monitoring data due to secure attachment throughout the sterilization cycle.

- Enhanced organization and traceability through clear labeling.

- Improved efficiency and reduced errors with time-saving features like pre-printed information.

Simplifying Your Sterilization Workflow: Easy Handling and Clear Documentation

This ETO indicator tape goes beyond just confirmation. It prioritizes your convenience and efficiency with features designed to streamline your sterilization processes:

Effortless Application:

- Strong, secure adhesion: Stays firmly attached to various materials throughout the cycle, eliminating worries about detachment and ensuring accurate monitoring.

- Flexible and tear-resistant: Handles easily without ripping or breaking, making application and removal simple.

Crystal-Clear Documentation:

- Dedicated writing surface: Write legibly with any pen or marker, allowing for clear labeling of lot numbers, dates, and sterilization cycles directly on the tape.

- Pre-printed options: Choose tapes with pre-printed lot numbers or sterilization cycle indicators to save time and minimize labeling errors.

Benefits:

- Reduced handling time: Easy application and removal minimize disruption to your workflow.

- Enhanced traceability: Clear labeling ensures accurate identification of individual items and sterilization cycles.

- Improved workflow efficiency: User-friendly features save time and minimize potential errors.

This ETO indicator tape doesn't just monitor. It becomes a seamless extension of your sterilization process, ensuring accuracy while empowering you to work efficiently and maintain clear documentation.

Beyond the Basics: Choosing the Right Tape for Your Needs

Choosing the Right Fit: Beyond Basics for Your Ethylene Oxide Sterilization Monitoring

While performance and usability are crucial, selecting the right ETO indicator tape involves several additional factors specific to your needs:

Cost-Effectiveness:

- Compare features and prices to find a balance between affordability and essential qualities. Consider bulk purchase options for high-volume usage.

Specific Needs:

- High-temperature resistance: For specialized sterilization cycles with higher temperatures, opt for tapes designed to withstand those conditions.

- Extended shelf life: If you require long-term storage, choose tapes with extended shelf life to ensure effectiveness when needed.

- Additional functionalities: Explore features like pre-printed information, color-coding, or compatibility with specific sterilization wrapping materials.

Regulatory Compliance:

- Ensure the sterilisation indicator tape complies with relevant regulations in your region, such as ANSI/AAMI ST79 and ISO 11140-1, Class 1.

- This guarantees adherence to safety and performance standards, fostering trust and avoiding potential compliance issues.

Remember:

The ideal ETO indicator tape isn't a one-size-fits-all solution. By carefully evaluating your specific needs and priorities, you can choose a chemical indicator tape that offers optimal performance, user-friendliness, and cost-effectiveness while adhering to regulations.

Additional Tips:

- Consult with sterilization professionals or equipment manufacturers for specific recommendations based on your setup and usage.

- Research and compare different brands and types of ETO indicator tapes available.

- Request samples or trial programs to test and evaluate the tape in your actual workflow.

By considering these factors and actively seeking informed choices, you can ensure you have the right ETO indicator tape to optimize your sterilization monitoring effectively and confidently.

Finding the Ideal Ethylene oxide indicator tape for Success

Choosing the Right EO gas indicator tape: Key Points and Informed Selection

Effectively monitoring ETO sterilization is crucial for patient safety and compliance. Understanding key factors like performance, safety, ease of use, and specific needs empowers you to select the best ETO indicator tape for your facility.

Key Points:

- Performance: Ensure accurate color change within specified EO parameters and consider independent testing data.

- Safety: Opt for heavy metal-free tapes complying with regulations and verify material compatibility.

- Ease of Use: Secure adhesion, easy writing surface, and additional features like pre-printed information can streamline your workflow.

- Specific Needs: Evaluate requirements like high-temperature resistance, extended shelf life, and special functionalities.

- Regulatory Compliance: Ensure the eto tape adheres to relevant regional regulations.

Informed Selection:

By carefully considering these factors and comparing available options, you can make an informed decision and choose the ETO indicator tape that perfectly aligns with your specific needs and priorities. This ensures optimal performance, user-friendliness, cost-effectiveness, and compliance, ultimately contributing to successful and reliable sterilization practices.

Remember: Informed selection empowers you to choose the ideal ETO indicator tape, safeguarding patient safety and upholding high sterilization standards within your facility.

[2]. CDC: [ https://www.cdc.gov ]

[3]. CIELAB color space: [ https://en.wikipedia.org/wiki/CIELAB_color_space ]

[4]. CIELAB ΔE: [ https://www.sciencedirect.com/topics/engineering/perceived-color-difference ]