Ultrasonic Cleaning Verification: Ensuring Sparkling Cleanliness in Critical Industries

Ultrasonic cleaning technology has become a cornerstone for achieving meticulous cleaning results in various industries, particularly those demanding high levels of sterility. However, verifying the effectiveness of ultrasonic cleaning goes beyond simply assuming the job is done. That's where ultrasonic cleaning check indicators come into play.

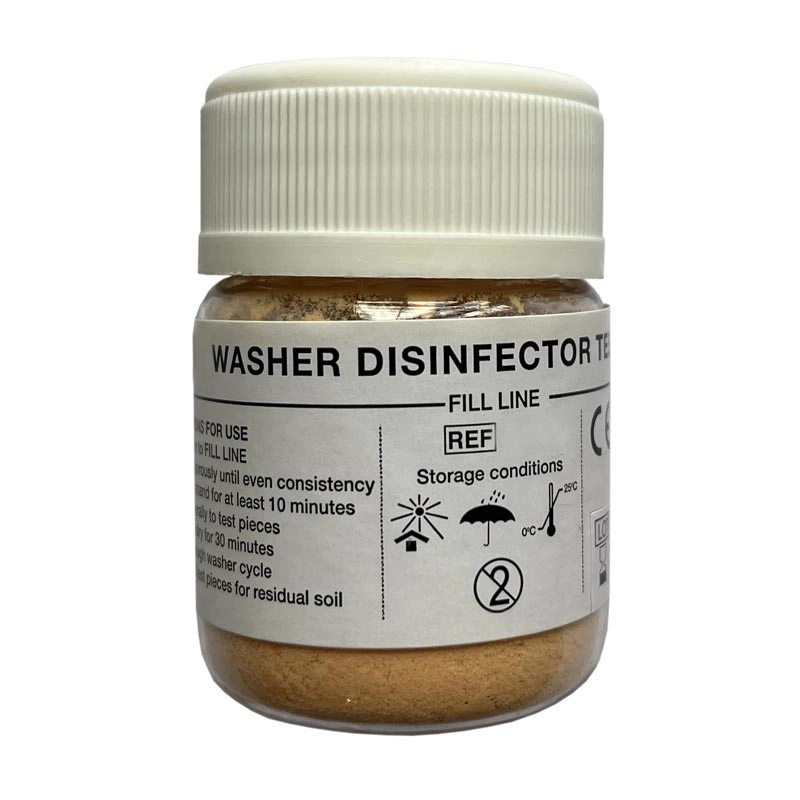

Think of these indicators as miniature test subjects, designed to mimic the challenges faced by actual items being cleaned. They provide a rapid and visual way to assess the cleaning efficacy, offering invaluable feedback for operators and quality control personnel.

How Do They Work?

During an ultrasonic cleaning cycle, the indicators, typically small strips containing test soil, are placed alongside the objects being cleaned. The ultrasonic waves and cleaning solution work their magic on both the actual items and the indicators. After the cycle concludes, the indicators are closely examined for any remaining traces of soil or residue.

Benefits of Using Ultrasonic Cleaning Check Indicators:

- Instant Feedback: Unlike complex lab tests, indicators provide immediate visual confirmation of the cleaning effectiveness. This allows operators to make quick adjustments if necessary, ensuring optimal cleaning outcomes.

- Visual Verification: Forget intricate lab procedures. These indicators rely on simple visual inspection, making them accessible and easy to use for staff of all levels.

- Enhanced Quality Control: In industries like medical, dental, and precision manufacturing, maintaining strict hygiene standards is paramount. Indicators contribute to robust quality control by verifying adherence to established cleaning protocols.

- Process Optimization: By analyzing the indicator results, operators can fine-tune cleaning parameters like time, temperature, and detergent concentration. This data-driven approach leads to improved cleaning efficiency and cost savings.

Beyond Visual Inspection:

While ultrasonic cleaning check indicators offer a valuable tool for initial assessment, it's important to remember that they primarily detect visible soil and residues. For detecting microscopic contaminants, additional analytical methods like particle counting or surface analysis might be necessary.

Industry Applicability:

The benefits of ultrasonic cleaning check indicators extend beyond medical, dental, and precision manufacturing. Any industry where cleanliness is critical, such as electronics, food processing, and aerospace, can leverage these indicators to ensure thorough and reliable cleaning.

Choosing the Right Indicators:

With various manufacturers and types of indicators available, it's crucial to select the ones suitable for your specific needs and cleaning applications. Consider factors like the type of soil, material compatibility, and desired sensitivity. Consulting with a reputable supplier like [Your Company Name] can guide you in choosing the right indicators for optimal results.

Remember:

Ultrasonic cleaning check indicators are a valuable tool for verifying cleaning effectiveness and enhancing quality control. By incorporating them into your cleaning procedures, you can ensure superior cleanliness standards and maintain peace of mind, knowing your critical instruments and components are truly sparkling clean.

Disclaimer:

While this article provides information about ultrasonic cleaning check indicators, it is not intended to be a substitute for professional advice or guidance. Always consult with qualified professionals to determine the best cleaning methods and indicators for your specific needs and applications.